Best 3D Printer for Miniatures, Warhammer, D&D & Wargames Models 2024

Last Updated on July 12, 2024 by FauxHammer

If you’re reading this I assume you are interested in 3D printing miniatures and/or Wargames Terrain. Great, because just below we are going to take a look at the current best 3D printers for Miniatures & Models. There are a lot of options to choose from and everyone has a certain need to balance with their own budget. Check our guide and follow the steps to get the perfect printer for you. (Updated article from best 3d printer miniatures 2021 and now best 3d printer miniatures 2022)

Please Note: This site uses affiliate links. Our Affiliate Partners are shown below

(Affiliate links will result in compensation to the site on qualifying purchases)

Click this link & buy your hobby stuff from Element Games for the UK & Europe to support FauxHammer.com – Use Code “FAUX2768” at the checkout for double reward points.

Our Affiliates / Hobby Stores

- UK: Element Games, The Outpost, Wayland Games, Mighty Lancer, Goblin Gaming, Forbidden Planet, Model Scenery Supplies, eBay, Amazon

- US/Canada: MTechCave, GameKastle, eBay (US), eBay (CA), Amazon

- Germany: Taschengelddieb

- Europe: eBay (DE), eBay (FR), eBay (ES), eBay (IT), Amazon

- Australia: eBay, Amazon

- Global: RedGrass Games, Warcolours

- 3D Printers: Phrozen 3D, Elegoo, Anycubic

FauxHammer – Latest Video on YouTube

The Best 3D Printers for Miniatures & Models – Summary

Already have a resin 3D printer? Miniatures and scale models are some of the most amazing things to create. It’s such a perfect combination of products for your hobby. But you can do much more with your 3D printer, Action Figures are another popular choice. If you love Warhammer specifically then this goes great when 3D printing parts for the Mcfarlane Warhammer Action Figures. Want another use for your 3D printer? Anime Figures, Scenery, Props, the list goes on. One of my favourite things to make with my 3d printer, lego figures. If you dream it, you can do it. One of the most popular uses in our hobby is with personalised games, such as d&d miniatures, 3D print is to D&D what butter is to bread.

If you want to watch this article rather than read it, you can see our video below

like the video, If you aren’t too bothered about any reasoning and just want to see the list, check out this quick summary below of the best 3D printers for Miniatures & Models.

But if you want our buying advice for your particular scenario, see the table

| Rank | Model | XY Resolution (AVC) | Print Volume (XYZ mm) |

|---|---|---|---|

| 1 | HeyGears Ultracraft Reflex | 33 µm | 191 x 121 x 220 |

| 2 | UniFormation GKTwo | 29 µm | 228 x 128x 245 |

| 3 | Elegoo Saturn 4 Ultra | 24 µm | 219 x 123 x 230 |

| 4 | Anycubic M7 Pro | 24 µm | 223 x 126 x 230 |

| 5 | Elegoo Saturn 3 Ultra | 24 µm | 219 x 123 x 240 |

| 6 | Elegoo Saturn 4 | 24 µm | 219 x 123 x 230 |

| 7 | Elegoo Saturn 3 – 12k | 24 µm | 219 x 123 x 250 |

| 8 | Anycubic M5s Pro | 24 µm | 218 x 123 x 200 |

| 9 | Phrozen Sonic Mini 8Ks | 22 µm | 165 x 72 x 180 |

| 10 | Elegoo Mars 5 Ultra | 18 µm | 53 x 78 x 165 |

| 11 | Elegoo Mars 4 Ultra | 18 µm | 53 x 78 x 165 |

| 12 | Elegoo Mars 4 (9k) | 18 µm | 53 x 78 x 165 |

| 13 | Anycubic Photon X6Ks | 34 µm | 196 x 122 x 200 |

| 14 | Elegoo Mars 4 Max | 34 µm | 196 x 122 x 150 |

| 15 | Anycubic Photon D2 | 51µm DLP | 130 x 73 x 165 |

| 16 | Mars 4 – DLP | 52 µm DLP | 133 x 75 x 150 |

| 17 | Phrozen Sonic Mini 8k | 22 µm | 165 x 72 x 180 |

| 18 | Elegoo Saturn 8k | 28.5 µm | 219 x 123 x 210 |

| 19 | Phrozen Sonic Mighty 8k | 28.5 µm | 218 x 123 x 235 |

| 20 | Anycubic Photon Mono 2 | 35 µm | 143 x 83 x 165 |

| 21 | Phrozen Sonic Mighty Revo (14k) | 24 µm | 218 x 123 x 235 |

| 22 | Anycubic Photon M5s | 24 µm | 218 x 123 x 200 |

| 23 | Anycubic Photon M5 | 24 µm | 218 x 123 x 200 |

| 24 | Creality Halot Mage S | 24 µm | 223 x 126 x 230 |

| 25 | Creality Halot Mage Pro | µm | 228 x 128 x 230 |

Best 3D Printer for Miniatures – Quick Buying Guide.

THIS PART OF THE ARTICLE IS CURRENTLY BEING EDITED. THE LIST ORDER IS NOW CORRECT BUT THIS NEEDS REFRESH WHEN I GET A MOMENT FREE

If you are after just a decent super low-budget 3D printer, I’d say go with the non-pro Elegoo Mars 3 while you can, at Sub $150 this will give you print quality fine enough for miniatures.

The thing that people to know clearly when printing miniatures is that in order to get the highest-resolution prints, you need a high-resolution printer and a high-resolution resin. But the highest resolution resins are typically very brittle. So the resulting model does not lend itself to being used in a tabletop game. or even being painted, or even being handled unless they only have super-chonky parts.

Print anything with a thin sword, long polearm or any of their fine extremities and you’ll find they easily just snap.

So the point is, you want a resin which cures with a little more rigidity, but the softer the final cured result of any resin, the softer the details of it. So it’s about finding a balanced resin of sharpness, but with some rigidity. Something we’ll get onto our recommendation on shortly.

But then you also have to consider the impact of voxels and layer lines on a miniature. meaningless on larger prints but obvious on miniatures, especially when you apply dry brushing and wash techniques to your paint job.

You can combat this easily on modern printers using antialiasing and image blur (a subset feature of antialiasing). But applying this also softens the sharpest details in your prints.

So the point is, any printer with 35-micron pixels (I’ll explain in a mo, just remember 35 microns) will be more than fine for miniatures. Anything below this offeres minimal to no benefit.

Best Best Beginner 3D printer

Now, if you are looking at this printer above as your first, you probably want to know what you can get if you spend just a little bit more. well for only another $40 (everything is in USD even though I’m British because all the brands’ list prices in USD and only some in GBP, so this is an easily comparable metric) get the Elegoo Mars 3 Pro, This provides the same quality as the printer above, but feels much better built, well, it feels less cheaply built. and it comes with a Carbon filter to remove smells and a preinstalled glass screen protector.

Like the model above, this is a 6.66-inch, 4K printer with a monochrome LCD. Elegoo has a great history of being the starting spot for printer enthusiasts with their huge community backing it up. you’re more likely to get peer-to-peer support with this brand than any other.

But if you are considering this, then also consider the newer Mars 4 Max, which again is just another $40, has all the features of this one, same print quality but with the benefit of a much larger build plate. A feature which I personally value above print quality, especially in the case of 8k printers specifically.

There are other printers that do the same as the Mars 4 max, but they cost so much more that this one becasome the easy pick.

From here we kinda make a big jump in terms of price, but also a decent jump in terms of size and bit of a jump in terms of quality.

Check Prices at Elegoo

Check Prices at Element Games

So if you want something a bit bigger and meatier, you’re likely to consider the Saturn 2 8k. (There’s also the 12k Saturn 3 now, but for miniatures, there’s only the tiniest benefit in getting one over the Saturn 2. and I doubt anyone would even notice that difference – so grab this whilst they still have stock)

The Saturn 2 has a bigger screen and a better resolution than the printers above, (resulting in 28.5µm versus the Mars 3’s 35µm) but costs more. RRP-wise – the Saturn 2 is double the price (but you can frequently get discounts and deals. Never pay RRP on these things). Y should see a bit of a difference in prints from this versus the lower-resolution ones, but again, it’s not huge.

If you can stretch to a Saturn 2, I’d say definitely get that, Especially as it’s heavily discounted to shift the remaining stock before the Saturn 3’s full release. The print quality output is nigh on par with something like the Sonic Mini 8k, almost, though not quite – but can your eyes even tell?! I Doubt it. Mine can’t.

The convenience of a far larger print bed is frequently worth more than the potential (inferred) resolution difference!

Check Prices at Elegoo

Again, We have more detail on printer resolution vs 4k 8k etc and why that matters (or frequently doesn’t matter) in the article below. and I will do all I can to drive this point home and save people money.

However It’s worth knowing that Elegoo also make the Saturn 8k, Unlike the larger Saturn 2, the 8k is similar in form factor to the original Saturn. The difference is that the Saturn 2 is slightly taller in its maximum print volume (a rare benefit for miniature printers). It also has a more powerful LED array, resulting in slightly faster prints. and when I say slightly, I mean 0.3 seconds per layer difference. it’s 5 minutes per 1000 layers, It’s nothing substantial, but it’s there!

Resulting Print-quality-wise, there’s no discernable difference between this and the Saturn 2, and it’s $100 cheaper, (RRP). Check our video below to see if you can see a meaningful difference between prints. If not, get the cheapest one.

The Saturn 2 is currently the perfect balance of size, quality and price. if you can afford it, get it.

Now, If you absolutely must have the best quality miniatures possible. Bearing in mind you need to use high-detail resin, which is very brittle. You probably want the Phrozen Sonic Mini 8k S it has the smallest pixels of any existing printer. Now alternately, if you want print accuracy over resolution, our recommendation over this is still the Anycubic Photon D2, which proves that DLP is the future of 3D printing technologies. It’s just so much easier to dial in because you get no noticeable loss of detail due to overexposure and LCD bloat.

Despite a much lower printing resolution, the sharpness of DLP (providing results close to those of the Mini 8k) coupled with Anycubic’s softer Craftsman Resin and Cheaper Price makes this a much more balanced choice. It’s super quiet, low energy and the projector lasts 10x longer than an LCD. It’s super fast with very little in the way of fumes. and unlike the Mini 8k, There’s far less to go wrong and because you don’t get anywhere near as much outward light bleed as you do with LCD printers. dialling the exposure settings in for sharp prints is a breeze.

However, you are limited by the size of the build plate. For miniatures, the Ultra is more than fine, but for vehicles and large 1-piece models, you could find yourself a bit stuck, unless the models are broken down into multiple components.

Now, Finally, on to my choice of the perfect all-rounder…

The best printer, hands down is the

The number one pick is easily the Uniformation GK TWO. Again, “EASILY” the number one pick. – and I’m still yet to hear even a rumour that any other brand has something in the works that would even come close. From a lesser-known brand (Phrozen were at one point) this printer already has the perfect balance of screen resolution and build size. You’ll be hard-pressed to find much of a difference in print quality between this and any other printer on this list, purely because resins themselves aren’t capable of rendering detail much sharper than what you can get here. (I’ll keep repeating it because so few people realise this adn we need to start spreading this fact)

But the convenience features of this model are worth so much more than anything the other printers offer. No screws and bolts to use or maintain this, everything is clipped in sensibly and firmly. But it also has an integrated heater below the resin vat which warms your resin for you! No longer do you need to warm up your garage/shed or spend hundreds creating an enclosure. Just plug it in, let it warm itself (which it does by default, though you can change the temp setting), and press print.

Fewer issues when printing lead to happier customers. This is far beyond anything else right now.

Everything else is in the middle of the road so read below what the benefits are (normally at the cost of print quality) to see if it’s the right printer for your needs.

The Best 3D Printer for Tabletop Miniatures, Wargames, Busts & Scale Models – Introduction

Before we begin properly, let’s get this out of the way. Now is the perfect time to get a 3D printer, miniatures, d&d, Warhammer, proxies, unique sculpts and more are readily available at comparable quality to retail products from your favourite brands. This is perfect for people who want truly unique d&d miniatures, 3D print them in just a few short hours.

Yes In 2022 it’s finally possible to recreate the model quality you’ll see from some of your favourite manufacturers, using consumer-grade home 3D printers. do you play Warhammer? 3D printed miniatures will probably be a very appealing prospect. and yeah you can easily just print a whole army of proxy models to use in Warhammer Games. Also, you can still print a ton of stuff to enhance your existing force, giving some incredible and unique style to your models.

However, It’s not only illegal to steal other company’s Intellectual Property, but just finding the 3d printer miniatures models to create such a force is nigh-on impossible, When you want the style of your 3D printed parts to match each other. Companies like Games Workshop are clamping down on the models which bear obvious similarities with their products. – though there is a growing number of companies out there providing, not only proxies, but also their own games. And this makes the idea of 3D printing for miniature gamers – highly attractive. You can make some incredibly decent 3D printed d&d miniatures or miniatures for various other games. Or even just to paint because they look awesome. 3d printing wargaming miniatures is so much fun!

If you want to know how to paint 3D-printed miniatures? well, thankfully it’s exactly the same as any other miniature and unlike most retail resin sculpts. Once fully cleaned and cured, you shouldn’t need to do any further cleanup and a primer will stick great. 3dpreinter and miniature models go hand in hand.

3d printing miniature figurines are really fun and rewarding, it’s essentially a hobby in itself. When you don’t need to worry about stealing from someone else’s IP. You can get some incredible creations.

In fact, generic models are aplenty online, if you’re looking at 3d printing tabletop miniatures or you’re after 3d printed RPG miniatures. Then there are sites which will let you design a custom model and download the file to print it with. This also extends to 3d printing ww2 miniatures and 3d print Napoleonic miniatures too. From full models to components, this opens up a whole new world of possibilities to many modellers.

There are certainly a lot of things to learn when it comes to getting the best out of 3D prints, supporting the components, printing orientation, layer heights and exposure settings. Then once printed you do need to deal with trimming down the areas which supported the printed model. But when you dial your printer in for its environment. You’ll soon and rapidly be printing miniatures at a higher quality than even the likes of Games Workshop produce.

Whilst the process of “whole models printed at 28mm” isn’t quite at its pinnacle yet. Larger models and slightly lesser detailed 3d printer gaming miniatures are still very achievable, even with the existing printers, people are improving on their model printing results every day.

The Best Tools For Miniatures?

FauxHammer.com is dedicated to finding the best tools for your hobby. Start with our list of Essential Hobby Tools which will lead you to find the Top-10 tools for each category.

To see all of our guides to the Best Tools for Miniatures, click on the image above.

2k Vs 4k Vs 6k Vs 8k Vs 12k Resin 3D LCD Printers

Wow, I hear you exclaim. This is an 8K 3D Resin printer, so details are twice as crisp as they are on a 4k printer, right?

Well, maybe, sure, yeah, Ummm….

Sorry about this bit, but most of the above is marketing spiel. Just like in the TV world, 4k means little more than the standard 3840 x 2160 pixels. but those pixels could be spread from over a few inches to over a foot depending on the screen size. This also assumes the manufacturer is using a standard aspect ratio. After all, 4k in itself is already a loose marketing term.

4K resolution refers to a horizontal display resolution of approximately 4,000 pixels”.

Wikipedia

“Approximately”. You see, 3840 isn’t even 4000 pixels across, but they have rounded up.

8k is further off the mark, with screens at only 7680px wide, itss called 8k, because it’s double the standard 4k. Wait until we see the 12k standard which is closer to 15,000 than 16,000.

So when you are looking at a 2k, 4k, 6k or even 8k printer. you also need to check the screen size. Because any 8k screen which is physically twice as large as an equivalent 4k screen has the exact same resolution for a model printed at the same size on each. Meaning print quality will generally be the same. The bigger printer in this example is only really better if you want to print larger things…

What you should really look for in regard to display resolution, which is pixels per inch (PPI). Few, if any, of the manufacturers tend to show off. Even when they are good.

You can easily calculate this by the diagonal in pixels over the diagonal in inches.

But to make it harder for you to work this out, manufacturers will provide the diagonal in inches, and display resolution in Height & Width. The real PITA companies will only give you the screen size in height and width too.

So just take the Square Root of (width squared) x (height squared) to get your diagonal – Thanks Pythagoras

Or you can just read the article below where we’ve done it for you.

As for FDM resolution. Its nozzle size is multiplied by how much material it splurges out per minute. (That’s a whole different ball game)

The Best Resin for 3D Printers for Miniatures & Models

This really needs to be a separate article which is overtly unbiased, but I have tested dozens of resins, different types of brands and consistencies, My upcoming series of videos will be putting different resins through various tests to compare their detail rendering with their toughness. As a general rule of thumb as I’ve said, Higher detail resins are brittle and crack, softer resins which create more sturdy prints have softer details. Water Washable and Eco resins are typically quite trash. if you want the benefits they offer, that’s fine just accept the drawbacks that come with them. I’ve seen more people have issues with these than the types that prefer to be cleaned with Isopropanol and/or Methylated Spirits.

The key to a good resin for miniatures is having something that is sharp first and foremost, capable of rendering the highest detail. Then for that sharpness, as sturdy as it can possibly be. It needs to resist handling, and packing in your army bag or box for game days/night and printed model parts need to survive the odd drop from a table.

I’ve had some favourites over the years, but most, like my previous favourite Anycubic DLP Craftsman resin, are still more on the brittle side than tough. but i liked how well it rendered details and the finish.

So that’s why we have released our own resin, in partnership with Yes that’s 3D printed you can now buy Wargamer Resin. “THE” resin was made with miniature printers in mind and it is now the only resin I personally use. Unless of course I’m required to use a brand’s specific resin in a particular printer review.

Wargamer Resin is made to be that perfect balance for you as Miniature Printers. It showcases high-resolution detail and it’s tough. Tougher even than retail models that come on sprues… The result is a miniature printed with a smooth surface that looks indistinguishable from a plastic moulded miniature, you can scrape down support marks as easily as you would scrape off mould lines. The whole point here is to stop worrying about what everyone means by 8k or ABS-like or all that guff because all the brands mean different things.

What this resin means is that we’re done with stupid names. Are you a Wargamner? then it’s the one for you. Do you want your 3D-printed miniatures to be just like what you would buy in a store? then it’s for you.

And as an added bonus. it’s Water Washable. I know, I know. I also hate water washable, and I almost refused to put my name on this stuff based on that fact alone. Then I printed it.

This is game-changing magic in a bottle of resin. To have everything you would need as a miniature printer and for it to be water washable. It really is something else.

Don’t trust me, try it yourself and be as amazed as I was, because this is all I use now.

The Best 3D Printers for Miniatures & Models

Below is a list of what we believe are the best printers and the order has been determined through my personal use of all the listed models, and I simply asked myself, Would I rather have this than that when printing miniatures? for each individual model. This used to be easy, whichever printer offered the better quality would be higher in the list.

But as we enter the 12k printer generation, we quickly realised that at least for our use case as miniature printers, these new units offer little to no benefit mostly because, as I’ve already said and will repeat many times again. The best resins for us produce prints a little bit more resilient than the sharpest of resins. and only those sharpest resins will see any improvement from the new generation, even then, it’s minimal – but those resins are incredibly brittle.

So now the list is ordered mostly by the preference of what the better printers truly are. It’s a balance between, resolution, features and price. but prices can frequently fluctuate as these brands consistently compete with each other.

So yeah, for each printer below I’ve wondered, would I rather use this, than all of those before it? and here’s the result

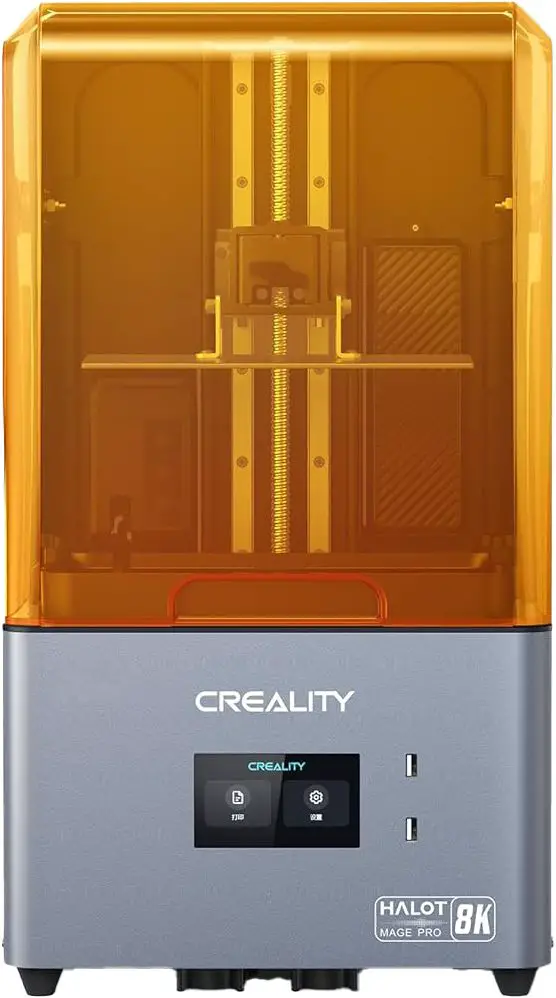

25. Creality Halot Mage Pro

Screen Size: 10.3″

Screen Resolution: 7,680 x 4,320px

Pixel Size: 0.0297mm (29.7µm)

Build Volume (XYZ): 218 x 128 x 230 mm

These first few printers exists on the list because I’m trying to respond to people asking the question “why didn’t you include X printer”, Well, it;s not that I haven’t tested them, it;s because I do not think they are worthy of your consideration.

Exhibit A

This could have been great, it had some interesting features at launch and is still one of the fastest “moving” printers out there. But just like FDM printers that keep pushing speed, this thing has gone well beyond the limits of the material you use it with. Resin can only be cured so fas and lifted from the release film so fast.

This can move at triple the speed that their own fast resin is capable of… why?

Coupled with a poorly laid out UI and unexplained advanced features that people are still trying to figure out. It’s just a lot of bad design choices in a world where people want ease. Check the video below for instance. this machine actually broke itself through normal use!

Unless you want fast prints and only fast prints using very brittle low quality resin, stay away.

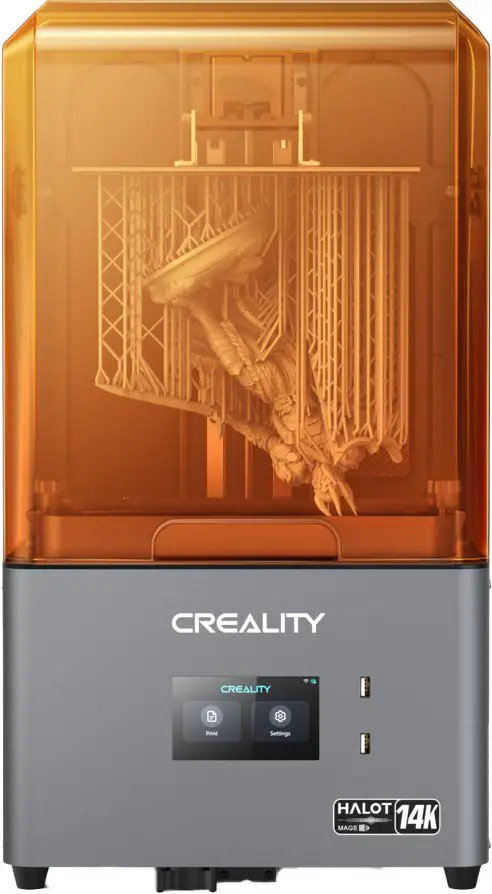

24. Creality Halot Mage S

Screen Size: 10.1″

Screen Resolution: 13,320 x 5,120px

Pixel Size: 0.024mm (24 µm) /0.019mm (19 µm)

Build Volume (XYZ): 223 x 126 x 230 mm

This is basically the same printer as above, but now with a 14k screen and they removed the resin pump which was terrible anyway.

It’s little better. The lack of the crappy pump helps and the air filter is now affixed to the back. But the UI is still a bit more complicated than it needs to be, and just like the Pro above, it is limited by Dynax mode, which means you can print fast, so long as you are happy with low quality prints. Or you can print painfully slow, with little benefit because I couldn’t actually get quality mode to work.

Again, unless you only want fast, stay away, but there are cheaper printers that will do what this does better!

23. Anycubic Photon M5

Screen Size: 10.1″

Screen Resolution: 11520 x 5120px

Pixel Size: Y-axis = 0.024mm (24 µm) / X-axis 0.019mm (19 µm) – (but it’s not very sharp)

Build Volume (XYZ): 218 x 123 x 200 mm

This list used to be easy to put together because we had clear categories of printers. 10″ 8k printers, 6″ 4k printers and a few outliers like the 6″ mini 8k and the DLP printers. But time and personal use have clearly shown me what people want in a miniatures printer. And it seems the vast majority of people, mostly want the sharpest printer they can get, at the largest size they can afford, with as many convenience features as they can muster. And the M5 series is just provably weaker in all of those categories than what has come before.

See our video for why.

So whilst Anycubic has done “something” to soften prints due to some intrinsic feature within their hardware – this serves nothing but to remove control from the end user. There was nothing wrong with the way 3D printers worked before – Such as the M3 Premium and Similar printers. The results were sharp and yes this would cause some level of voxelization on the prints where you had sharp edges, but by enabling antialiasing and image blur you could all but combat that to the point these layer marks were imperceivable.

With these, the result is – softer prints. you still need to enable that antialiasing to remove layer lines, but now, because the print is already softer. this softens them further – diluting the details even more.

Don’t get me wrong, this printer is still fine for larger prints like busts and scenery. But that’s all it is… “fine”

My hope and prayer for Anycubic at this point is that they make an M5 Premium model which actually competes with the Saturn 3, because this just doesn’t.

22. Anycubic Photon M5s

Screen Size: 10.1″

Screen Resolution: 11520 x 5120px

Pixel Size: Y-axis = 0.024mm (24 µm) / X-axis 0.019mm (19 µm) – (but it’s not sharp and uses ACF film which blurs prints even more)

Build Volume (XYZ): 218 x 123 x 200 mm

Like the M5 above, this printer has an S at the end of its name. And in this case, that S means Speed. An inconsistent designation considering that with other printers in Anycubic’s lineup, S means something different which suggests it means very little at all. It’s a confusing addition which serves little more than to confuse people. Just like Anycubic did when they announced this printer – but did not mention the M5 at all. leading many people to preorder it believing the marketing that this is the next best thing! Only to find out… it isn’t.

And whilst this has extra features that do make the printer worth more than the base M5, for people who want detailed miniatures (most of us) you will need to swap out the ACF Film with NFEP in order to achieve the best results. which are on par with the printer above and are also, as I previously mentioned “ok”. But still worse (Softer) than many last-gen printers.

It’s not necessarily a bad printer, it’s just not good either. if this is your first 3D printer, you will be happy with it. but if it’s an upgrade then I only hope you are upgrading from a smaller 6″ 4k printer, or it isn’t much of an upgrade for miniature printers.

The target audience for this printer is those who want speed. Coupled with Anycubic High-Speed resin, along with the included ACF release film, you can print the entire height of the build plate in under 2 hours. meanwhile, as I type I currently have a print of a 32mm miniature on another printer, and it’s taking 6 hours.

Check our video on this printer for clear details of its performance.

That’s because I’m using a high-detail resin that requires a very slow lift speed and am printing at 30-micron layers. I’m doing this to print the best quality miniature I can. But that’s fine. I can’t paint faster than I can print already. I like most people am happy enough with current speeds and know that speed is determined more by the resin I’m using than the printer.

In order to get the speed benefits from this unit that it advertises. you must use that resin, which has quite sharp results but is also brittle. It doesn’t look great in photos before paint because has some natural translucency – a trick that some resin brands will use to make prints from their raw resin look better (but often makes them more brittle due to the extra pigment).

But also to get that 2hr print of the full height, you must use 0.1mm layers, 100-microns. Double that of the standard most people use and over triple what I use on miniatures. The resulting quality is, well, it’s awful by comparison.

And the ACF film also reduces detail on prints too, which you can see in my comparison video of these two printers. This also shows that this printer is capable of better quality using this Anycubic High-Speed Resin, just by slowing it down.

Now, if you want speed and this significant cost to quality, then fine go for this. but I’m hedging my bets that next to nobody does, not when printing miniatures

But it does have some extra features like fully automatic bed levelling and failure detection. so if you want quality you can still buy this printer, and swap the detail-obscuring ACF film with normal NFEP, as is used on the M5. It will stop you from doing the ultra-fast prints unless you swap back, but you do still get those automation features

Are they worth the price difference? they aren’t to me. but that’s just me.

21. Phrozen Sonic Mighty Revo (14k)

Screen Size: 6.6″

Screen Resolution: 4096 x 2560px

Pixel Size: 0.035mm (35 µm)

Build Volume (XYZ): 143 x 83 x165 mm

Phrozen were one a top name in the Resin printers game, Once… and this is not the worst printer on the market, in fact it’s better in several ways than many other below. But the Janky inclusion of new features couple with it;s price point makes me go “woah…” and not in a good, Bill & Ted, kind of way..

This printer feels like the embodiment of an argument between Phrozens Marketing Team deciding what features users want, and Phrozen’s engineering team jamming them in because some higher-ups agreed with marketing.

The result here is a heater which blows hot air away from the resin. It will probably still take the edge off and warm it up in a room which is already standard room temperature., but in a cold environment you’ll need to put it in an insulated enclosure to have any chance

Other features like the carbon filter which is not even attached to the UI needs to be turned on and off manually separately to the printer. and it;s behind the build plate… so you need to awkwardly press it over the vat as the print starts, or under the vat before a print and risk getting dripped on.

Check out the video for more details

Then there’s the Timelapse camera, painfully low resolution at 480×640 pixels and whilst there were some firmware issues preventing the light coming on in sync with shots on launch. but the light is still in front of the camera lens overexposing shots, and there’s nothing you can do about it but live with the glare

It’s a good machine, it’s just not worth this price IMO

20. Anycubic Photon Mono 2

Screen Size: 6.6″

Screen Resolution: 4096 x 2560px

Pixel Size: 0.035mm (35 µm)

Build Volume (XYZ): 143 x 83 x165 mm

A half-decent starter printer for anyone, Honestly, if you are printing miniatures. this is pretty much the quality level you need. You’re unlikely to get much better print quality when you consider what resins you’ll probably be using for miniatures. yes, there are printers out there which provide sharper details. but only if you are using sharper resins, which are typically more brittle and do not suit tabletop gaming pieces during practical use. because those sharper resins create really brittle models. fine for larger sculpts – but for miniatures, steer clear.

With 35 micron pixels, this is as detailed as you ever truly need, and beyond this level of quality, in most cases, you’re paying for minimal improvements to detail, if any is even noticeable. So the value really comes from build plate size and usage convenience. Of which, this has none.

It’s the most bare-bones basic printer of this resolution out there from a wider-known company. So basic that everything about it looks and even feels cheap. Like the really soft plastic hood and the Little Plastic Legs on the base which causes this printer to slide all over the place from the briefest of little knocks. Sit it on a silicone mat, which is also useful for cleaning prints.

But it does the job, so if this is your first 3D printer intended to just cut your teeth with the hobby, wade in.

Check out our video on this which shows the printer in full, and also serves as an excellent primer as to why 12k, 8k, and 4k etc are pretty useless metrics on their own.

So yeah, it does the job, just don’t expect anything special and you won;t be disappointed. The next step up from this is a printer with marginally better build quality but also has features like the integrated, internally powered carbon filter for handling those nasty smells.

19. Phrozen Sonic Mighty 8k/12k

- Screen Size: 10″

- Screen Resolution: 7680 x 4320 px

- Pixel Size: 0.0285mm (28.5 µm)

- Build Volume (XYZ): 218 x 123 x 235 mm

There seems to be a pattern with 3D printers emerging. Phrozen is often first to come out with a printer range. in this case, it was a 10″ 8k printer. And they don’t rush them out, the build quality of these units is incredible. But then a few months later, the other brands come out with a similar printer of the same quality spec. but they normally add slightly more to the build volume and significantly reduce the price.

And that is exactly what has happened here.

The Mighty 8k rode on the coattails of the Mini 8k and was the first of this quality and size to market. and they deserve our support (by purchasing their stuff) so they can keep innovating and driving the industry forward.

Check out our review of this awesome printer by watching the video below

For a long time, this was a great little sweet spot for people looking for incredible quality and larger print areas. unfortunately, it’s hard to resist the printers below with their lower price and slightly taller build volume.

You can now buy the Upgraded 12k version which has a slightly sharper screen.

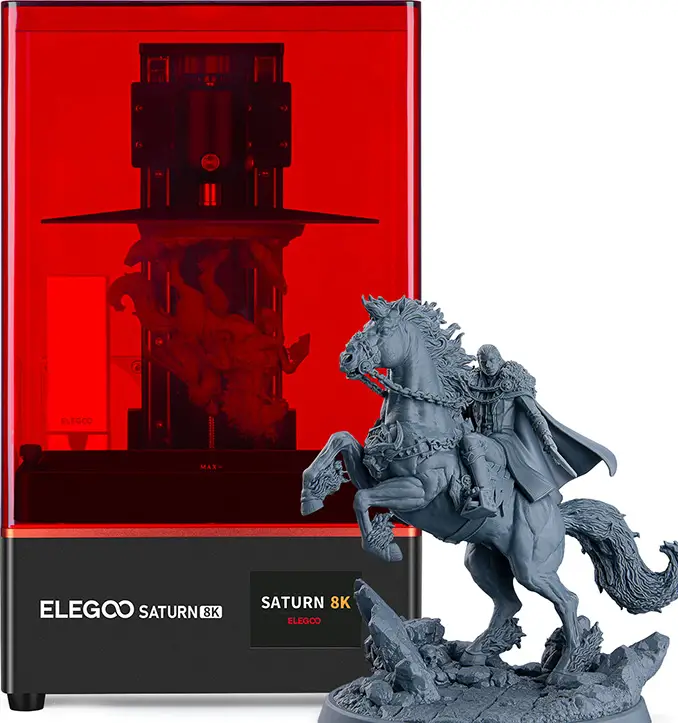

18. Elegoo Saturn 8k

- Screen Size: 10″

- Screen Resolution: 7680 x 4320 px

- Pixel Size: 0.0285mm (28.5 µm)

- Build Volume (XYZ): 219 x 123 x 210 mm

What is Elegoo doing? Well, my guess would be – making sure they are cornering the market. I’ll be honest with you, this printer should have been on this list a lot sooner, but despite me keeping an eye on the announcements from 3D printing companies. I didn’t even know that the Saturn 8k was a thing.

Even now, if you search Google or Amazon for “Saturn 8k”, you’ll get the Saturn 2 as the primary result. (because it’s frequently called the “Saturn 2 8k”). But this “somewhat hidden” gem is all but essentially the same thing. it’s just a little bit smaller than the Saturn 2 on the z-axis. but it’s a fair chunk cheaper. Almost a hundred dollar-pounds cheaper!

Over Xmas 2022, Elegoo even had an offer on where you could get the Saturn 8k with a Wash & Cure for less than the price of a Saturn 2!

So with the price difference, what are you missing here?

Well, the main one that sticks out is the form factor, unlike the angular style of the Saturn 2, this is essentially similar in profile to the original Saturn, but with the Saturn 2’s 10″ 8k screen.

It still comes with a tempered glass screen protector, and an internal plug-in carbon filter just like its bigger brother.

The print volume has been slightly reduced, but this is only in the z-axis. For miniatures. that’ 4cm loss is nothing! most miniatures will

The difference with the internals is that the Saturn 8k uses a 28 Lamp UV light source, whereas the Saturn 2 has a 48 LED array and a fresnel lens. In theory, this should provide us with more intense light and the fresnel lens should help to focus it and make it more uniform.

In reality, will this mean faster prints with sharper accuracy? probably not.

Check out our video on the Saturn 8k

Where people seem more worried about picking this up over the Saturn 2, is because the Saturn 2 has such a large user base already, where this seems hidden in the bowels. Is the concern that as the popularity of the Saturn 2 grows and this Saturn 8k potentially dwindles (despite it being the newer release). is that this could have a limited shelf life, making spare parts hard to come by.

But if you want a printer “now” and are on a budget. yes, this will give you 95% of what a Saturn 2 gives you at a much lower price… The resulting print quality from each printer would be indistinguishable.

17. Phrozen Sonic Mini 8k

Phrozen Sonic Mini 8k Specs

- Screen Size: 7.1″

- Screen Resolution: 7500 x 3240 px

- Pixel Size: 0.022mm (22 µm)

- Display Resolution: 1152ppi

- Build Volume (XYZ): 165 x 72 x 180 mm

15% off Phrozen with code: “FAUXHAMMER23“

The (not so mini) Mini 8k is the present pinnacle of LCD quality. Whilst the screen has a weird aspect ratio (it’s far wider than it is tall) it is still the highest resolution screen available at this size.

The details this thing can produce are absolutely superb. and it’s here where the line between companies like Games Workshop and what you can print at home – truly start to blur. Yes, you can print better than Forgeworld quality models with this thing.

However, in my situation, I have not had the best, out of box, experience for printing miniatures. But that is mostly due to some technical issues I’ve had. and I must admit, Phrozen’s Customer Service has been superb. Not only were they straight to the point but they even reviewed my posts in their Facebook Community page (unprompted) to get more detail about the issues I faced.

Once set up, however, this thing pretty much eradicates layer lines (z-axis) and voxel/graduation lines (X & Y-axis)

Don’t believe me? well check these out, these are Space Marine Accessories printed on one of our Mini 8K printers. no Anitailising applied, these are as direct to the 3D file as you can get. And go-on. find a layer line? Try…

These parts are nigh on par with production-quality models. I know a lot of people worry that printing will kill Games Workshop. That’s highly doubtful, but it has certainly changed the landscape for the quality of the miniatures – now very much in favour of 3D printed parts.

You can see this printer in use in our review video

Whilst resin prints aren’t as convenient to work with as GW’s HIPS plastics. What this Mini 8k printer can produce, definitely provides better quality (read as “sharper and more accurate”) parts than what Forge World put out.

If you want maximum detail on your miniatures this is your first real choice.

For more on the Sonic Mini 8k, you can Check out our Written Review

16. Mars 4 – DLP

Screen Size: 6″

Screen Resolution: 2560 x 1440px – But it’s DLP

Pixel Size: 0.052mm (52 µm) – But it’s DLP

Display Resolution: 498ppi – But it’s DLP

Build Volume (XYZ): 132.8 x 74.7 x 150 mm

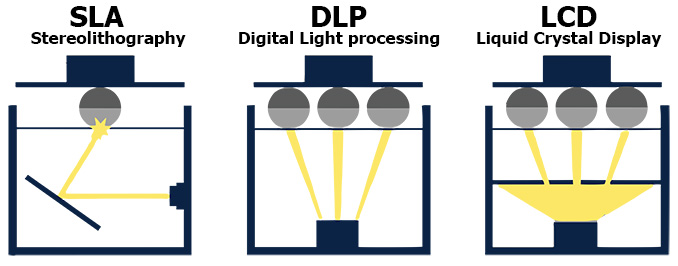

DLP is a different technology from MSLA. if you are confused by the acronym that’s fine. DLP basically means the printer uses a projector and MSLA is every other typical printer on this list that uses an LCD – assume printers are LCD/MSLA unless it specifically says they are DLP, like this one.

Because DLP printers cast light only in the shape of the layer they are creating. The result is a much sharper print. LCD have large Light arrays below the screen, as that light comes through the screen, it does not travel upwards directly toward the build plate, so each layer has some element of bloat as light travels outward along the XY plane too. New technologies in Light array projection will combat this. but DLP still performs far better in terms of layer accuracy.

Yes, it’s only 51 µm pixels, but it’s 51 µm and it’s sharp. for those concerned this will result in more voxelisation on prints, you can combat this with Antialiasing, just as you would need to with an LCD printer. The result here is still a more model-accurate print with sharper edges being rendered in the print just like they are on the 3D model render.

The greatest benefit is that because of the aforementioned sharpness, or more specifically, lack of LCD bloat. Dialling in a DLP printer is far easier. The curing time per layer range for a successful exposure is wider on DLP printers than with LCD. adn when you cure smaller items (like supports) they are typically stronger. Once again leading to more accuracy and more success.

You can see this printer in action by watching our Mars 4 DLP Printer Review below

There are further inherent benefits to these printers too, DLP is a lower-power technology. The components operate much cooler, Powerful blower fans are not needed. The units operate much quieter, last 20,000 hours rather than 2,000 hours of LCD’s and consume far less power whilst in use.

Whilst this comes with a Carbon Filter, it’s also marginally larger on the XY area than the D2, this also means those pixels are marginally larger too (less quality), It’s the tiniest amount. it’s 1 micron. but it’s there.

You also lose 1.5cm on build height too.

15. Anycubic Photon D2

Anycubic Photon Ultra Specs

Screen Size: 5.9″

Screen Resolution: 2560 x 1440px – But it’s DLP

Pixel Size: 0.051mm (51 µm) – But it’s DLP

Display Resolution: 498ppi – But it’s DLP

Build Volume (XYZ): 130 x 73 x 165 mm

So, this was the second consumer-grade DLP printer to exist, as direct sequel to the Photon Ultra. Whilst it feels a bit cheap with its mostly plastic components, including the resin vat. – it’s managed to get our number 1 pick!

Put simply, it’s just so much easier to use than an LCD printer. LCD printers can overexpose and bloat details on a print softening sharp edges. you need to dial them in to 0.1 or even 0.01 seconds per layer to get the perfect exposure time. But on DLP, because the light is so direct, you hardly get any outward light bleed. so once you have the minimum exposure time locked in, you can often go several seconds above that with no discernable impact to print detail.

From our own personal experience, we’ve been able to print higher-quality miniatures on this, far more easily than with the Phrozen 8k – (please note, results will vary from person to person. but my OOB experience was superb). That’s even more impressive when you learn that the resolution is only somewhere around 498ppi (51µm pixel size) (WHAAAAAATTTTT! That’s only 2k, we had those years ago!)

Yeah, that’s 4x less than the Mini 8k, and is actually the lowest XY resolution on this list, well, it shows initially. The huge difference between these and LCD printers is that DLP printers are super sharp when projecting light. Instead of projecting a whole chamber of light and having an LCD block it out (leaving some light bleed around the edges, these DLP models actually project light in the shape of the layer, and only that much light toward the resin. Very Precise.

To visualise the effect, think back to the original Apple iPhones before they created retina displays. remember before retina how you could make out the individual pixels if you looked close enough? Well here, it kinda goes back to that the projected light is so sharp that you can make out the edges of individual pixels that make up a layer.

But by adding 16x antialiasing and 2x Image blur in your slicer, you’ll pretty much make all of that disappear. But because DLP’s projects direct light, you still get super-sharp details in the final result whereas an LCD panel will always have some outward light projection no matter what you do.

If you want to see the D2 in action, printing Warhammer equivalent models from OnePageRules and larger models, then see our detailed review video below which will also guide you through getting the best possible miniature quality from it.

The added benefit to getting this printer for miniatures is that the included DLP Craftsman Resin is sharp but still quite soft and has some comfortable flex to it, whereas the resin included with the Mini 8k is quite firm and brittle. With that resin you only need to pick up a miniature the wrong way and parts can snap off. With this stuff, it should easily survive the odd drop or fall.

When it comes to prepping miniatures to paint. support marks are easily just pulled away and scraped down, (much like mould lines) when using this stuff.

14. Elegoo Mars 4 Max

- Screen Size: 9.1″

- Screen Resolution: 5700 x 3600 px

- Pixel Size: 0.034mm (34 µm)

- Build Volume (XYZ): 196 x 122 x 150 mm

I would honestly say that this is now the best choice for an entry-level printer. Yeah, you can get the smaller Mars 3 or Mars higher resolution Mars 4? Mars 4 Ultra models. But as I’ll say often, you only get the benefit of those higher resolution printers if you are using high-resolution resins – which are far more brittle than resins you would want to use when printing miniatures you’d actually want to use. So practically speaking, the difference between these 34-micron printers and the 10″ 28.5-micron printers below them is minimal.

It’s hard to pick a printer right now because we are in a generational crossover with 6″ and 10″ printers all getting resolution upgrades. as just mentioned though, those upgrades are nigh on pointless to most miniature printers.

So the reason to choose this printer would be if you are looking at something like the Mars 3. For not too much more, you could have this printer, which offers the same print quality but the convenience of a larger build plate.

But also when you look at this, for not much more you can get a Saturn 2 with a larger plate still and the increased resolution. So until those older printers are sold out. I’d say it’s still better to pick one of those last gen models up at a discount, just because this offers nothing new, other than a choice in the middle, which will be more relevant when the Saturn 3 and Mars 4 are on general sale.

13. Anycubic Photon X6Ks

- Screen Size: 9.1″

- Screen Resolution: 5700x 3600 px

- Pixel Size: 0.034mm (34 µm)

- Build Volume (XYZ): 196 x 122 x 200 mm

What does “S” even mean to Anycubic? When it comes to the M5 series, the S clearly means Speed with the M5S having things like the ACF release film and the faster motor than the M5. But when comparing the Mono X 6k to the Mono X 6Ks. They look entirely different and have different specs. When you interrogate those. In this case, the S printer, this printer, has weaker specs and is cheaper. unlike the M5 where the S is the feature-rich more expensive unit. WTAF Anycubic, do you enjoy confusing your buyers?

But despite that ridiculous mix-up where S now seems to mean, Smaller. it is only a marginal difference. and the printer itself is fairly decent. And I was unsure where to put this in the list in relation to the Mars 4 Max because they both have the same screen area, but the build volume here is 5cm, taller. Whilst you may not need that when printing miniatures it may be worth it in some case – like when printing scenery.

But you need to decide if the value of having that is worth the price difference between this and the directly competing model above. That’s your call to make. because they both print the same quality models.

Check out or video on this printer below

But I also just prefer this printer – With no intrinsic benefit, I like the build quality of the mechanical components, I like the UI more. The lid does not sit on the base as cleanly as I would like because mine was warped in transit and the lip around the base is shallow. but this is the sort of engineering Anycubic should be promoting. Far over what they have done with the very cheapened M5 series.

Just a shame it costs so much more than a competitor printer which all but does the same thing.

12. Elegoo Mars 4 (9k)

- Screen Size: 7″

- Screen Resolution: 8520 x 4320 px

- Pixel Size: 0.018mm (18 µm)

- Build Volume (XYZ): 153 x 78 x 165 mm

The Mars 4 Ultra is currently the highest resolution printer on the market when we look at pixel size. With only 18 Micron pixels. the next closest is the Sonic Mini 8k. yes the 12k printers have 19 micron pixels. but that’s only on the x-axis. because those 12k screens have rectangular pixels, so the Y-Axis is 24.

Here it’s 18 Microns Everywhere!

However, with that being said, this is also one of those new generation printers where resolution doesn’t equal sharp prints. We have gotten so low now with resolution that the more important feature of these printers is Lightsource.

See this in action by watching our Mars 4 9k Video

Don;t get me wrong, I;m not saying this is a bad printer, not at all. But when you compare the XY resolution on this to the Mars 3 for example, it;s not much better in terms of detail rendering, where it does improve however, is with Surface smoothness.

When this was released there were some issues with Antialiasing, but I would argue that at 18 microns, you don’t really need it. print at 0.02 mm layer height and this is one of the most detailed printers out there, despite prints being a little on the soft side.

11. Elegoo Mars 4 Ultra (9k)

- Screen Size: 7″

- Screen Resolution: 8520 x 4320 px

- Pixel Size: 0.018mm (18 µm)

- Build Volume (XYZ): 153 x 78 x 165 mm

If you like the look of the Mars 4, the ultra version is almost the same thing, but with some added features and some caveats.

Let’s talk about UI, WiFi and print Speed.

First of all, the Mars 4 Ultra is essentially just a Mars 4 (9k) and I say 9k because there are so many printers in the mars 4 like, it;s hard to tell which one I mean without specifying mars 4 (9k). Try it. google the Mars 4 and see how many results show you that printer rather than the Ultra, the DLP or the Max?

But anyway, the Mars 4 Ultra has a completely different motherboard inside which is more powerful. Thanks to this, you get a much more in-depth UI with features like the ability to edit a print’s exposure settings on the printer itself.

To see more about these features and more, check out our Mars 4 Ultra Video

Now you may be wondering from the Thumbnail above, What is ACF? Well, ACF is a new type of release films which allows for faster printing speeds. But bbe aware that not only is this film softer and easier to puncture, but it also reduces surface quality somewhat. For larger geometric shapes this is generaly fine, but when printing miniatures, It leaves a surface quality w’d find unacceptable on a detailed print.

Thankfully you can just swap this ACF film for PFA film and get the same print quality as shown in our comparison vieo below

They are both good printers, but if you are after quality over features, you can get better. and by that I mean sharper.

10. Elegoo Mars 5 Ultra

Elegoo Mars 4 Pro Specs

- Screen Size: 7″

- Screen Resolution: 8,520 x 4,320 px

- Pixel Size: 0.018mm (18µm)

- Build Volume (XYZ): 153 x 78 x 175 mm

The Elegoo Mars 5 is a great piece of hardware. Elegoo came out with a new approach in 2024 by delivering an affordable tilting vat module. Whilst they didn’t invent it as it has been on other printers in both consumer and industrial applications. Making it this accessible is a gamechanger.

The Mars 5 Ultra is a great little machine. But the tilting vat is what makes it stand out the most. This feature reduces peel forces which in turn reduces print time significantly. probably twice as fast as other printers. of equivalent size.

And it does all this using PFA release film, whichg for miniatures is great as ACF will leave surface marks on your prints. ACF is a different release material used to increase speed as Seen in the Mars 4 Ultra and Saturn 3 Ultra among others.

But this also means there are fewer settings to worry about too, because speed is controlled on the printer.

This machine also boasts an AI camera which can be used to create timelapses, but its crap/useless in the dark

On the drawback side, whilst is has 18µm pixels, prints just aren’t as sharp as they are from larger printers like the Saturn 3 and Saturn 4. Likely due to the density of micro-cables in the LCD which reduces UV light transmittance. But this is just an inference, no matter what i do. I cannot get prints as sharp as they are on the 12k/14k machines

We are splitting hairs here, well, we are splitting tiny fractions of hairs, but Check the video for more info

There’s also an annoying space in the build plate for resin to accumulate during prints

but regardless it;s a great machine, a good beginner unity due to the fewer settings and pretty powerful at that. Though if yo are spending this much, can you not push a bit further and get the Saturn 4 Ultra instead for the larger volume and sharper prints?

9. Anycubic Photon M5 s Pro

Screen Size: 10.1″

Screen Resolution: 13312 x 5120px

Pixel Size: 0.024mm (24 µm) / 0.019mm (19 µm)

Build Volume (XYZ): 224 x 126 x 200 mm

This is basically the m5s again, in fact it is the m5s again, but this time they added a heater and a 14k screen

This got moved far up the list from those other because the screen prints are notably a touch sharper than those. but only a touch. But it;s here mostly because the convenience of a heater, that blow hot air towards the resin in the vat. may be the icing on the cake that some people who need a heated printer

And whilst this is auto levelling, even though it;s really not. you can adjust this one unlike the original M5 at launch. But be aware, any cubic have cheeped out on this so much that they didn’t even put rubber stoppers in the feet. Check out the video above for why this is a problem. and if they cut corners here, where else are they cutting them inside?

It works, it does the job, but the whole M5 series just feels cheap when compared to other machines

8. Phrozen Sonic Mini 8ks

Phrozen Sonic Mini 8ks Specs

- Screen Size: 7.1″

- Screen Resolution: 7500 x 3240 px

- Pixel Size: 0.022mm (22 µm)

- Build Volume (XYZ): 165 x 72 x 180 mm

15% off Phrozen with code: “FAUXHAMMER23“

The new Mini 8k S is still the present pinnacle of LCD quality. And it beats out the old Mini 8k in almost every way. Now that Phrozen has designed out many of the quirks of the initial models and reduced the cost of components significantly. using their own controller board rather than buying in from the likes of ChiTu Systems as everyone else seems to do. Though it’s also bundled with a year of Chitu Pro Slicer… Worth $169.00 a year on it’s own! Wow…

Whilst the screen has a weird aspect ratio (it’s far wider than it is tall) it is still the highest resolution screen available at this size.

The details this thing can produce are absolutely superb. and it’s here where the line between companies like Games Workshop and what you can print at home – truly starts to blur. Yes, you can print better than Forgeworld quality models with this thing. Easily…

Unlike my experience with the original Mini 8k, which, did not go well but still resulted in an amazing printer, This unit worked for me perfectly out of the box. Coupled with the Phrozen 8k Resin, this results in what are still the ultimate in quality when it comes to prints on consumer MSLA printers.

Whilst for a long time, we marked the much lower resolution DLP printer above this, when you consider the price of the unit versus those.

Once set up, this thing pretty much eradicates layer lines (z-axis) and voxel/graduation lines (X & Y-axis)

Don’t believe me? well check these out, these are Space Marine Accessories printed on one of our Mini 8K printers. no Anitailising applied, these are as direct to the 3D file as you can get. And go-on. find a layer line? Try…

These parts are beyond production-quality models. I know a lot of people worry that printing will kill Games Workshop. That’s highly doubtful, but it has certainly changed the landscape for the quality of the miniatures – now very much in favour of 3D printed parts.

It comes with an integrated screen protector which is a welcome addition, and the UI for controlling Phrozen printers is more intuitive than most of their rivals. Phrozen certainly put quality at the forefront of what they do, and this shows through and through – despite the price-point.

You can see this printer in use in our review video

Whilst resin prints aren’t as convenient to work with as GW’s HIPS plastics. What this Mini 8k printer can produce, definitely provides better quality (read as “sharper and more accurate”) parts than what Forge World put out.

If you want maximum detail on your miniatures this is your first real choice – not bad considering it’s currently at entry-level prices!

7. Elegoo Saturn 3 – 12k

- Screen Size: 1011″

- Screen Resolution: 11520 x 5120 px

- Pixel Size: Y-axis = 0.024mm (24 µm) / X-axis 0.019mm (19 µm)

- Build Volume (XYZ): 219 x 123 x 250 mm

The Elegoo Saturn 3 is the sharpest LCD printer I have ever used. Unlike other printers in the 2023 12k lineup, you can actually see a benefit to the increased resolution on this model over the 8k versions that came before. But only under specific circumstances. Those circumstances being… you must use incredibly high-detail resins. Mostly those labelled as 8k, Such as Elegoo 8k Space Grey, Phrozzen Aquak 8k. and as another contendeer Sirayatech Fast.

But for miniatures, those resins are also very brittle. Extremities will rarely survive a 15cm drop, but worse still is that fine components like bladed weapons or polearms can snap even if you just pick them up the wrong way. This is fine for ultimate quality display pieces if you are really careful, never drybrush small and thin parts. and never touch them again once painted. Don’t even look at them too strongly.

So I’m explaining all that because, when you print miniatures, you need resins which cure softer, but the drawback of that, is that these resins cannot render as much detail. So you need to find that balance. The resin we use now for miniatures is Wargamer because we feel it has that perfect balance of sharp detail, but still, the perfect amount of toughness & flexibility to exceed that of production plastic miniatures. But with this, or even with other sturdier resins You do lose the ability to render the finest details. it may render overall prints a bit smoother, but it’s a “bit” I would not consider has any value to the vast majority of miniature hobbyists.

Check out our Saturn 3 Video for more details

So when you jump from 28.5 Micron pixels of the 10″ 8k printers to 24-micron prints of this. The difference is all but pointless for practical miniature printers.

But Yes, it is still technically more capable than the Saturn 2. And I know a lot of people would prefer to have a printer with this rendering capability but not use it than someday want to use it but never have it.

The TLDR is; If you are printing miniatures. Just save yourself some money and get the Saturn 2 or equivalent printer, especially whilst stocks last and Elegoo are selling it cheap. But if/when they are sold out. yeah, grab one of these because it’s the newer version.

6. Elegoo Saturn 4

Elegoo Saturn 4 – 12k Specs

- Screen Size: 10.1″

- Screen Resolution: 11,520 x 5,120 px

- Pixel Size: Y-axis = 0.024mm (24 µm) / X-axis 0.019mm (19 µm)

- Build Volume (XYZ): 219 x 123 x 250 mm

The Saturn 4 is a mild upgrade to the Saturn 3, but that’s about it, afterall, print quality is identical. same screen.

It has some goo enhancements, but before I list them. Go look at the Saturn 3 and check it’s current price, if it is significantly lower than the 4, is the following worth it as an upgrade

- An up-and-over lid

- A self levelling build plate*

- A sexier UI**

*The Self levelling build plate Elegoo has given us is not self levelling, but most all the brands do a similar thing and call it self levelling. Basically the build plate has springs, so when it touches the screen, those springs compress to make the plate and screen parallel. when they are touching anyway. as soon as it lifts up, those springs decompress and push the plat back to where it was.

On the one hand this is a pointless feature, and you can adjust it for better accuracy. But it does generally make printing easier at the cost of potentially inaccurate base layers.

** And the UI is a bit prettier, something I have asked Elegoo for for a while. and it is also slightly more functional because you can change a few of the print parameters on the printer itself rather than having to reslice a file for a small change.

But again is that worth it to you for the price difference between it and the Saturn 3? that’s the whole point of my video below

It will be really interesting to see what people go for with these two.

5. Elegoo Saturn 3 Ultra

- Screen Size: 10.1″

- Screen Resolution: 11520 x 5120 px

- Pixel Size: Y-axis = 0.024mm (24 µm) / X-axis 0.019mm (19 µm)

- Build Volume (XYZ): 219 x 123 x 250 mm

Easily one of the best all-round 3D printers Ever made. The Saturn 3 offers a quality level that’s indistinguishable from printers with a much lower pixel size. And for the First I’ve seen in a Printer, the ACF film I got on it smooths out prints rather than leaves an odd cross-hatched texture which is arguably worse than the voxel and layer lines it was designed to eradicate.

Please check out our video for a thorough breakdown of all of the Saturn 3 Ultra’s features.

Whilst other videos have pointed out that the Saturn 3 does not have a huge quality difference when compared to the Saturn 2. I feel they have missed a lot of the innovation that has gone into this incredible printer.

This printer’s custom Refractive Light Source results in sharper prints from the get-go. The thick ball-screw allows for much smoother motion from the build plate, reducing errors like layer shifts and being a strong support for this machine’s incredible speed.

That’s not all either. This comes with a better build plate levelling system than the base model by adopting a 4-point screw mechanism found on most other printers these days.,. You can also filter out more smells by installing a second Carbon filter inside the unit. You need to buy the second one separately, but there is a port for it.

Finally, the convenience of Wifi is so useful. I’ve complained for ages that the USB drives you get with 3D printers are terrible and die quite quickly/ but with this printer, you don’t need one. Slice your models using Chitubox, which is included on the USB Drive (OK, you may need to use it once), at the end of the slicing process. choose Network Print and send the file over, you can start it remotely too.

The Elegoo Saturn 3 Ultra is by far Elegoo’s best printer and whilst it is on the more expensive side of options. it is worth far more than what you are paying for it. The biggest issue Elegoo could have is having enough of these units in stock to cover demand over the coming months!

4. Anycubic M7 Pro

Anycubic M7 Pro Specs

- Screen Size: 10.1″

- Screen Resolution: 13,320 x 5120 px

- Pixel Size: 0.017mm (17 µm) / 0.024mm (24 µm)

- Build Volume (XYZ): 223 x 126 x 230 mm

This is a breath of fresh air from Anycubic following a dismal performance with the M5 which cheapened the whole brand. the M7 is a step back into the realms of quality they were heading to ward with the M3 Premium. the best printer that hardly anyone bought and had a limited shelf life.

Anycubic have gone an interesting way with this one. But for simplicity, think of it as an M5 with much better build quality for starters. Prints from this can be as good as those from printers like the Saturn 3 and Saturn 4. but there are hoops to jump through to get that.

See the video below

So this comes with ACF by default, which reduces print quality to a degree you will notice on miniatures. So to get the best quality from this you need to also buy a sheet of PFA film and go through the annoying process of changing it over. and when you do that, all the speed benefits from this machine are gone. It is relegated to the speed of any standard printer with teh lift and retract mechanism.

But where this gets extra points is the inclusion of a heater. So many people say, I don;t need a heater, i live somewhere hot, but the point of a heater is to maintain resin temperature consistency throughout the print rather than just get it hot. Even in warm climates, you have night-time and a 5degree shift can be the difference between high quality print and fail.

Now whilst this has a heater, it does it an odd way, it actually pumps resin through a small channel in the vat, into a heating element and then back out into the vat, so not only is the resin constantly moving throughout your print. this is another thing to clean and flush out between prints…. yay?!

But when you jump these hoops and are ok with the cleaning of this pump. it;s a good printer.

3. Elegoo Saturn 4 Ultra

Elegoo Saturn 4 Ultra Specs

- Screen Size: 10.1″

- Screen Resolution: 11,520 x 5,120 px

- Pixel Size: 0.019mm (19 µm) / 0.024mm (24 µm)

- Build Volume (XYZ): 219 x 123 x 250 mm

The Mars 5 ultra is a printer that impressed me from the get go. Making tilting technology affordable is the single most impressive generational leap i have seen in resin printing yet.

This machine houses several powerful features in a smart way. the icing on the cake is this tilt mechanism, which is just incredible. it speeds up prints, there are fewer settings to worry about and it stops you getting little air bubbles on the tops of your curved model surfaces, it’s just ace!

And allof that comes before the fact it still uses PFA rather than ACF, so you get the benefot of printing 3x faster than normal printers but without any surface artefacts.

The Camera is a bit useless because it won’t work in the dark, but I talk more about that in my video.

With the included features like WIFI with direct printing and monitoring from chitubox it;s a handy printer.

it has some quirks like the build plate gap causing resin to build up and the gap around the LCD isa hazard you could spill resin in.

and despite the lack of including of a heater, which is coming separately and attaches to the vent hole on the back, this is still a marvel which has no earthly business being as cheap as it is. they could have charged $150 more and it would still have been worth it!

2. UniFormation GKTwo

UniFormation GKTwo Specs

Screen Size: 10.3″

Screen Resolution: 7680 x 4320px

Pixel Size: 0.029mm (29 µm)

Build Volume (XYZ): 228 x 128x 245 mm

Don’t worry if you haven’t ever heard of UniFormation, they are about to become a big name in the 3D printer scene. It’s not often when a relatively unknown brand even gets a look in, in the 3d printer space. A space which is dominated by the other 4 brands on this page. Most of the time, your smaller brands will make cheaper clones of existing products, but even when there are differences or the printer attempts to be unique. It is marred by the poorest of implementations and localisations, leading to more usage drama than it’s often worth.

So what must a small up-and-coming brand do to get any ounce of recognition in this oversaturated market? And how has a small brand absolutely trumped every other feature of the leading brands to become our top pick?

It fixes almost every problem I have with all the other 3D Printers!

I’ll quickly list the benefits, but for an in-depth breakdown of why this all matters, keep an eye out for my upcoming youtube video. We’ll be having some (multiple) giveaways of this printer when the video goes live – so make sure you’re subscribed.

- Flip-Up Cover – No longer need to find an extra surface space to dump the lid, it also has plenty of access to the inside. Unlike previous attempts at using this method where a front fascia would open up, the sides also open.

- Quick Release VAT – no more screws means no more forgetting to tighten the screws before starting a print – we’ve all done it!. just push the tray into place and it locks down!

- Factory Installed Screen Protector (and a spare in the box) – not only does this protect the screen from spills but it’s more than your typical sheet of clear filp that sits on the glass. This protector surrounds the whole screen and extends seamlessly onto the chassis to ensure everything is well protected.

- Easily replaceable LCD = 4 screws allow you to lift the screen out of the base, and 1 small ribbon cable is easily accessible.

- Links to free super awesome models are included on the USB drive – why don’t more companies do this? it’s free awesome stuff for you and free advertising for model creators.

- Pre-levelled build plate – this is factory levelled, you should not need to do it!

- Quick release Build Plate -no more bolts to twizzle. Just flip up one latch and remove it…

- Lip around the build plate – how many times have you removed your vat and in the process of flipping it round to access your model, it drips off a corner onto your desk, floor or you? this plate has a small lip around the edge to catch those minor spills

- It copies files to local storage before printing – No more need to worry about your included cheap USBB drive failing mid-print. when each print is started, the first job is to fully copy that file to the local internal storage memory. So even if the USB drive dies halfway through a print, the print will still succeed.

- A Resin Heating Chamber!!!!!! – I’ve saved the best for last and I’ll go one better, I’ll give this its own section below.

Check out our Video Review of the Uniformation GKTWO

If you have resin printed before, you may be aware that the biggest challenge is temperature. Especially in colder climates and for those printing in their Garage, Shed, Basement or Loft. It’s harder to heat these spaces in and around your home. So it should be great to know that this is a problem no more! Resins are very volatile when it comes to temperature and the difference between 20°C and 15°C is significant. One will lead to a decent print, the other will lead to, errors, brittle prints and even complete failures…

The Uniformation GKTwo heats the chamber below the Resin, not too much so that it damages or causes early degradation to the components. (LCD or LIght Array). In fact, they rate their LCD for 3000 hours whereas other companies only suggest 2000. This heat transfers through the LCD to the resin in the VAT. Heating the chamber above would leave the cured resin too soft and cause print failures which is why the ceramic heaters have only been placed in the chamber below.

In reality, As I am now able to print in my office with all the printers here at 20°C-22°C, I have had a lot of success lately. In my latest YouTube video comparing 10″ 28.5 Micron printers, I get the best exposure at 1.5s per 0.03mm layer on each printer. But thanks to the added local temperature increase from this printer, the resin is far more reactive, giving me marginally sharper prints at only 0.75 seconds. That’s a 50% reduction in curing time! So not only is this LCD rated to last 50% longer than its competitor printers, but with an additional 50% reduction in curing times, you can potentially get 100% more prints off one of these printers too!!!

Not only have Uniformation come out with a strong offering, but they have brought to the market a series of features that every other brand needs to include now if they even want to be looked at as a top pick!

1. HeyGears Ultracraft Reflex

HeyGears Ultracraft Specs

Screen Size: 13.5″

Screen Resolution: 5788 x 3667px (est)

Pixel Size: 0.033mm (33 µm)

Build Volume (XYZ): 191 x 121 x 220 mm

There are 3D printers for Hobbyists, and then there’s the HeyGears UltraCraft reflex.

Despite my initial resistance to this machine, it has significantly grown on me to the point that, for printing models for myself and friends, this is now the only machine I will use. Though it comes with a massive restriction that may just be too much for some people, and there are some limitations. too when compared to other modern printers. Regardless of this, It is, hands-hands down, without a doubt, the best printer I have ever used. And it keeps getting better.

Argue with me all you want that this is too locked down and will not allow you have the flexibility that pretty much all of the others offer. Hell, I’ll agree with you, and I won’t judge anyone for walking away from this once they learn how it;s locked down. BUt’s actually won me over, once you have this in your hands and can feel the build quality of the product, coupled with the quality of the prints from it compared to the absolutely no effort you put in. You can’t help but fall in love with how simple resin printing can be.

So to cut to the chase, this printer uses it’s own proprietary resin, you can put other resins in it and they will work. but doing that defeats the whole purpose of this machine. All of the various materials available for this are dialled in so accurately by the manufacturers. That this machine, despite it’s larger 35µm pixels, has provided better quality models than any other printer I have ever used!!!

This printer solves nearly all of the biggest problems in Resin 3D printing. except the cleaning process.. the wash station for this is kinda silly.

But the biggest problem in resin printing, is exposure settings. Now if I’ve learned anything in my time doing this work. it’s that the getting printer settings for any particular resin, is a pain in the ass. But it’s more than that.

I’ve done videos showing people how to dial in exposure settings to get prints working, and this is the most basic approach I could offer. Print a flat test a few times and then up your exposure settings a bit. if you want to dial it in more, use the Cones of Calibration as a better indicator that most presupported models will print. But, believe me, this is just to get your printer… printing stuff. My guides only scratch the surface of dialing in a resin printer.

But do you know what I’ve learned from this… Most people out there, don;t even want to do this much, people just want to get settings from someone else and have them work. If you’ve been around resin printing for a bit, you’ll know why this doesn’t work. but basically it;s environment. Forget your printer and resin combo, have you considered temperature and humidity because that matters.

If you have a heater in your printer that balances the equation somewhat, but again, this will get you ok settings.

Have you considered UV intensity? Early layer wait times? UV Wavelength? XY- Compensation, Shrinkage Compensation? All of those things and more, coupled with the variables like resin and temperature all play a crucial part in the results of your prints. And it’s the difference between “prints”, and nigh-on-perfect recreations of of the 3D render on your machine.

Other printers print things, This prints master-quality models every time, and that’s just the start!

Check out my video below which shows this beast in action.

The limitation is that to get all the benefits of this printer, it is centred around their-own proprietary resin. Which has been expensive, until their recently released PARP10 which is now below £50 per bottle. And Wargamer resin is £50 a bottle. I really like this PARP10 resin for miniatures too. It doesn’t have the same plastic feel or surface texture as Wargamer. but it’s very much like Anycubic’s Craftsman DLP resin, which I loved for a very long time! i still do.

And here, the details are out of this world!

I rejected the proprietary resin approach for so long, but the more I’ve thought about it, the more I’ve realised there is no other way to do it. There are so many resins out there. Unlike FDM printing where we have materials like PLA, PETG ABS etc, where they are all coming closer together and printers typically now have decent settings for these types out of the box. With resin, There are no clearly defined categories. So many resins and they are all so different. ABS-like means 3 different things to 3 different brands.

So unless you want to learn down to the nth degree how to get the perfect results from your resin/printer (and I don’t even know half the tests you’d need to perform), and you;re willing to put the time and resin in. There is simply no way to achieve this accuracy on your own. This printer comes with that by default

And, This printer is so good at knowing the support strength needed in order to hold onto a model of a certain volume. The Autosupport function of their slicer, (the best slicer app i have ever used), I actually prefer to use auto supports on this printer over any of the presupposes from some of the best model makers in the industry. because they are so small, you cannot see them after removal.

So, you can get any of the other printers on this list, dial it in for your chosen resin and be happy, please, be happy with your purchase before anything else. but you can buy those printers and dial them in to whatever degree you want to get a level of quality you are happy with.