🛒 Check out the GK3 Here – https://geni.us/Unfomation

💸 Save $30 on GK3 T (T-Screw Version) – Use code: FauxHammerGK3T30

💸 Save $40 on GK3 B (Ball-Screw Version) – Use code: FauxHammerGK3B40

Gustave Model by KC STudios https://www.instagram.com/kcstudioprops/?hl=en - If you haven't already, You should play Expedition 33! You'll thank me!

🔥 Loot Studios (Model Addiction Incoming)

Sci-Fi – https://geni.us/LootStudiosSciFi

Fantasy – https://geni.us/LootStudiosFantasy

Freebies – https://geni.us/LootStudiosFreebies

🎧 Hear more hobby rambling on @thepaintingphase

🎯 Photonsters XP Range Finder – https://www.thingiverse.com/thing:6023738

▶️ Watch Setup Guide – https://youtu.be/Gm0-z971tgY

🧼 Printer Cleaning Mat – https://geni.us/3DPrinterCleaningMat

🎨 Artis Opus FauxHammer Essentials Set – https://store.artis-opus.com/products/fauxhammer-mixed-brush-set-5-brush-deluxe

🖌️ Best Airbrushes – https://www.fauxhammer.com/top-10/best-airbrushes-for-miniatures-wargames-models/

💨 Beginner Airbrush Guide – https://www.fauxhammer.com/featured/best-beginner-airbrush-for-miniatures/

Show More Show Less View Video Transcript

0:00

All right, we've covered the GK3s,

0:02

and if you're thinking threes, yeah,

0:04

that's because there's two of them, not

0:06

including this one, the so-called Pro.

0:08

And that's what we're diving into today.

0:10

It's mostly the same, slightly

0:12

different, but those tiny changes do

0:14

give us some surprisingly different

0:15

results. So, join me as we uncover why

0:18

Pro is both the perfect name and

0:20

possibly completely the wrong name for

0:22

this machine. Hi, I'm Ross and this is

0:25

Farhammer Videos. Now, if this is your

0:27

first time watching one of my GK3

0:29

reviews, welcome. But I'm not about to

0:31

spend the next 20 minutes repeating

0:32

everything I said in my GK3's

0:36

review. You can watch that, too. And I'd

0:38

love it if you did because it goes into

0:40

way more detail. And another view, like,

0:42

and comment really helps the channel.

0:44

But for now, I'm just going to give you

0:46

a quick summary. So, with the GK3 range,

0:48

and that's not including the larger

0:50

Ultra, we've now got three nearly

0:52

identical machines with only a couple of

0:54

subtle differences. On the normal GK3s,

0:57

the nonpro versions that I covered in my

0:59

last video, one has a ball screw, the

1:01

other has a lead screw, also known as a

1:03

T-crew. The difference between those and

1:05

this Pro is that this has a ball screw

1:08

as standard with no T-crew option. But

1:11

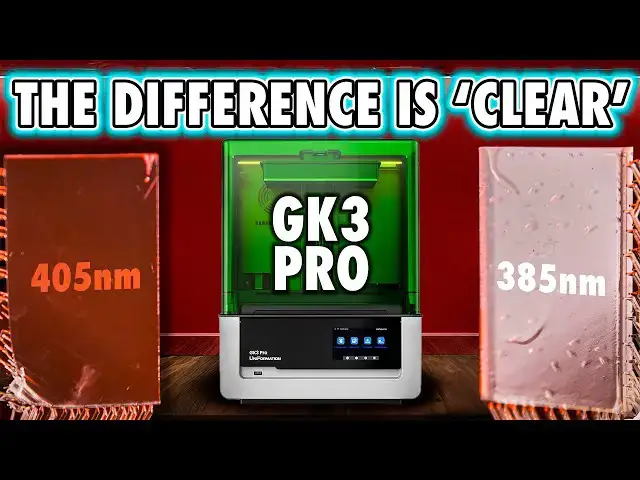

more importantly, this Pro uses a 385

1:14

nanometer light source, where the

1:16

standard uses a more common 405. In

1:19

fact, this is one of only two printers

1:21

I've ever had that uses 385. and I'll

1:23

come on to show what that means later

1:25

on. Continuing the summary for now.

1:27

Outside, the lid design's decent, but

1:29

there's a weird VOC leaking gap that

1:31

shouldn't be there. USB port placement

1:33

is smart, but recessed too far for some

1:35

drives. I love the power button being

1:37

moved to the front, but they hid it

1:39

under a rotating plate. The build plate

1:41

is still one of the best. Great texture,

1:43

solid locking, and no need for faffing

1:45

with leveling, assuming you get yours

1:47

pre-leveled. If you don't, really easy

1:49

to do, and it'll never come unlevelled

1:51

again. The VAT's big, though. with the

1:53

resin pore spout makes pouring awkward.

1:55

They fixed the bill plate drip tray slot

1:57

kind of, but it's a bit of a bodgege.

1:59

The screen is 16K, 9.6 in, not 10 as

2:03

some brands claim. Great resolution, but

2:06

limited UV penetration due to new panel

2:08

trends. The real win of this whole range

2:10

is that the screen replacement is

2:12

stupidly easy, and that is a genuine

2:14

selling point versus something like the

2:16

Saturn or M7. And some standout features

2:19

include a decent internal heater, a

2:21

pre-built-in air filter with printable

2:23

exhaust, and the auto resin system,

2:26

which I personally won't use. It's also

2:28

got a webcam, and an app, which finally

2:31

lets you watch prints in real time. But

2:33

then there's the UI, which is still

2:35

basic. Overtheair updates don't work,

2:37

and the multi-exposure test is basically

2:39

useless in many scenarios. In the end,

2:42

it's a printer that exists. It works

2:44

great. It's got some great reasons to

2:46

buy it. It's just not smarter than its

2:48

competitors. In fact, it's genuinely

2:50

dumber. But it is more convenient in

2:52

some real ways. The build plate, the

2:53

app, live webcam, and that replaceable

2:56

screen specifically, they're standout

2:58

features, and that's true of all of the

3:00

GK3 machines apart from the Ultra. But

3:03

what does this 385 nm light source

3:06

actually mean? And what does it do?

3:08

Well, if I'm going to explain technical

3:10

stuff, I need to do it in a medium that

3:12

I am actually comfortable with. Crayons.

3:15

Hopefully my editor can turn these

3:16

scribbles into something halfway decent

3:18

on screen. But for now, let's keep it

3:20

simple, not because you can't handle the

3:22

detail because this stuff is easier to

3:25

get right when we strip it back. And if

3:27

you've got better info or want to

3:28

clarify something, please drop it in the

3:31

comments. We're all figuring this stuff

3:32

out together. So, when we talk about

3:35

wavelength, the wavelength is just the

3:37

distance between two peaks or two

3:39

troughs in an energy wave. 385 nanometer

3:43

light has a shorter wavelength than 405

3:45

nm, which means it squeezes more peaks

3:48

and dips into the same distance. And my

3:52

high school physics teacher, the

3:53

absolute legend, Mr. Grl, once called

3:56

this its jigability, and that stuck with

3:58

me since I was 13. And why does this

4:00

matter? Well, more jigability means 385

4:04

nm light burns out faster. It carries

4:06

more energy per photon, but it doesn't

4:09

travel as far. So, it doesn't penetrate

4:11

as deep as 405 nm. All right, settle

4:15

down. It's width that matters anyway.

4:17

And I've got neither. And I've still got

4:19

kids, so clearly it works, and that's

4:21

what matters. Now, yeah, that's a crude

4:23

analogy, but it fits. And unfortunately,

4:26

it also lines up far too well with how I

4:29

actually feel about the existence of

4:30

this printer, but we'll come back to

4:32

that in the conclusion. But the primary

4:34

benefit of this change is one that we

4:36

can clearly see when using transparent

4:38

resins. The difference is visible, but

4:40

again only when using transparent

4:42

resins. The more opaque the resin, the

4:45

less this matters visually. So whilst

4:47

it's technically doing something, that

4:49

difference becomes less and less

4:50

noticeable the more pigment your resin

4:53

contains. Now I need to mention that the

4:55

normal GK3 uses PFA release film with

4:58

its marketing name.

5:00

But on the Pro, you don't get PFA. It

5:03

comes with CPFA, which if you want, we

5:06

should say stands for crap PFA, but it's

5:08

just a marketing word that Uniformation

5:10

have since admitted it's ACF. And

5:13

they've explained that this is a newer

5:15

ACF with a finer grain, but yeah, you

5:18

still get the surface texture just like

5:19

you would with ACF. And maybe that's not

5:22

a huge issue for you if you're printing

5:24

bigger models and you don't really need

5:26

a perfect smooth surface or if you're

5:29

printing with transparents because if

5:31

you want that glass-like texture, you're

5:33

going to need to clear coat them anyway.

5:35

And I've got a separate video on that if

5:36

you want to follow along and get

5:38

glass-like results from any clear resin.

5:40

But to really show off the difference in

5:42

penetration depth, Uniformation have

5:44

created several samples which have

5:46

cavities within solid objects. So, the

5:49

idea is with a reduced penetration

5:50

distance, there'll be less bloating in

5:52

the GK3 Pro printer. So, we'll be able

5:55

to see those internal structures because

5:57

they won't be filled in by the UV light

6:00

penetrating as deep. And yeah, you can

6:02

see it. If you're specifically after

6:04

something like this application in resin

6:06

printing, that's the difference. Less

6:08

bloating on transparent resins. And I

6:11

need to stress again, this is only on

6:14

transparent resins. The more opaque your

6:16

resin is, the less of an impact this

6:18

penetration depth will have. Now, to

6:21

cover my ass, because I am still new to

6:24

this, I will also say that there's an

6:25

argument for resins cured with 385 nm

6:28

lights being tougher, but I expect that

6:31

just like the penetration depth is a

6:33

minimal amount. In my hands-on

6:36

experience, I haven't noticed models

6:38

printed in normal resins break any

6:40

differently to ones printed on 405

6:43

nanometer resins. And to be clear, all

6:46

of this was done with the settings

6:47

Uniformation told me to use. But I've

6:50

also printed exposure tests on both

6:52

machines which are both balanced. I've

6:54

got another video on balanced exposure,

6:56

meaning perfect exposure, and why that's

6:58

not great, but why this works. Again,

7:00

check that. But this is enough to tell

7:02

me that yeah, I'll happily concur that

7:04

the settings uniformation provided are

7:06

solid for what we're trying to achieve.

7:08

But going back to the ACF release film

7:10

you get on these printers and why

7:12

uniformation of advised that this is

7:14

needed. Apparently, it's because the 385

7:17

nm light source will actually make PFA

7:19

brittle much quicker and could reduce

7:22

its lifespan in upwards of 50%. And

7:25

that's because of its increased

7:26

jigability. And I just haven't printed

7:29

for long enough and don't have enough of

7:31

these machines to actually test this,

7:33

put it through its paces and verify it.

7:35

But I also know I have another printer

7:37

which has a 385 nm light source and that

7:40

uses PFA release film. And I haven't

7:43

changed the film on that in about a year

7:45

or so since I got it. The printer keeps

7:47

telling me to do so when it says it's

7:49

run out and I just keep lying to it and

7:52

saying I have. Shut up. And that's why

7:54

Skynet will come to hate us. But on that

7:56

other printer with PFA film, I've come

7:58

to my third round of release film

8:00

ignorance and it's still printing. But

8:04

then on the other hand, I also trust

8:05

Uniformation wouldn't just make this up

8:07

and promote something as a necessity on

8:10

their machine when it'll be seen as a

8:11

negative by so many people and they know

8:14

it will be. I've had that conversation.

8:16

But that's it. Now look, in summary, I

8:19

am sure this is a great printer, and I

8:21

even trust that 385 is a better light

8:23

source in general terms, but the

8:26

difference here is only really visible

8:28

on transparent resins. Now, that's not a

8:31

bad thing. Any incremental update is

8:32

still an update, but the benefit also

8:35

comes with a promoted drawback. And once

8:37

again, I'll use the term apparently, it

8:39

degrades the PFA film significantly

8:42

faster, which is why they ship it with

8:43

ACF instead. And that makes the whole

8:45

endeavor feel like one step forward, one

8:48

step back, and therefore we haven't

8:49

actually moved. And we had the same

8:52

thing when ACF came out. Yes, it's

8:53

faster, but it reduces surface quality.

8:56

And as many, many people have echoed

8:58

now, people don't want ACF. They get

9:01

resin printers for the best quality. If

9:04

ACF reduces it, then that's not a thumbs

9:07

up thing for the majority. And I have to

9:10

say, and this has been widely debated as

9:12

well, but in my experience, and I can

9:14

only talk about my experience, I see it

9:17

as a weaker material, too, as in it's

9:20

not as strong. It doesn't last as long.

9:22

I've already had this one tear a small

9:24

puncture in the time I've used it, which

9:26

led me having to replace my screen

9:27

protector. And I can promise you now,

9:29

this isn't because I tried to start a

9:31

print with loose cured resin in the

9:34

back. But yeah, here we're told we need

9:36

to use ACF because 385 wears out PFA too

9:39

fast. Again, we've gained more accurate

9:42

transparent prints, but again, we've

9:44

reduced surface quality. And that

9:46

reduction in surface quality extends to

9:48

everything else you print, too, not just

9:50

transparents. So, this does one job

9:53

really well, but it does other jobs

9:56

worse. So, if you're looking at getting

9:58

this, I think there's there's two

10:00

options. You can accept the surface

10:02

quality issue and print away. Fantastic.

10:04

Thumbs up. Crack on. Or you could

10:06

replace the ACF with PFA and accept that

10:09

you might need to replace your film more

10:11

frequently. And if you do that, please

10:13

let us know what it's like for you in

10:14

terms of lifespan. Is it any better or

10:17

worse than what you've seen before?

10:19

Because I think we do need some

10:20

community consensus on this topic. And

10:22

we need more brands chiming in, too. I

10:25

want to be clear and say I haven't

10:26

concluded my opinion on this light

10:28

source yet. I just don't personally see

10:30

a benefit for my use case, but I don't

10:33

use transparent resins very often. And

10:35

what I want is the smoothest surface

10:37

quality possible so I can prime and

10:39

paint my models immediately. So, this is

10:42

one I just want to put out to the

10:43

audience. I'm not the gospel voice on

10:45

this. My opinion is not everyone's. So,

10:48

more so than ever, I open the floor to

10:50

you. Do you see the benefit here? Do you

10:53

get more than what it takes? Will these

10:55

benefits apply to you? And why? or do

10:58

you feel like me that this is an upgrade

11:00

but with the drawback of release film

11:02

that cancels out the benefit? I

11:04

genuinely want you to tell me. But

11:06

either way, I think it's the naming and

11:09

approach to releasing this that I think

11:10

is a huge misstep from uniformation. I

11:14

do think Pro is the best name for this

11:16

device because well, very specifically,

11:18

I think it's mostly for manufacturing

11:20

and prototyping professionals who will

11:23

genuinely see a benefit in this light

11:26

source. But I also see it as the worst

11:28

name from a marketing standpoint because

11:31

I think general everyday users will see

11:33

pro and immediately assume better than

11:36

the non-pro version and buy it without

11:38

realizing that that there are some

11:40

drawbacks that need to be considered.

11:42

Drawbacks that may not matter to you

11:44

depending on what you're printing, but

11:46

things that you should know about

11:47

specifically around surface quality and

11:50

model scale. Now, personally, I think

11:53

all of them should have just been one

11:54

product, the GK3, and let you choose

11:57

385, 405, T-screw, or Ballcrew on a

12:01

single product page rather than making

12:03

two, well, technically three separate

12:05

products that likely just confuse people

12:08

more than drive sales. But honestly,

12:10

overall, I feel this is just the

12:13

incorrect product for Uniformation to

12:15

have pushed to YouTube creators because

12:17

I genuinely don't think that the people

12:19

who would be tangibly getting the

12:21

benefits out of this machine are

12:23

watching YouTube hobbyist videos for

12:25

their buying choices. And the majority

12:27

probably aren't buying uniformation

12:29

printers in lie of things that are much,

12:32

much more expensive. But hey, I could be

12:35

wrong. I often am. I was wrong about

12:37

something 20 minutes ago, but I am

12:39

married after all. In all seriousness,

12:41

if you do fully understand the benefit

12:43

of 385 nanometer and specifically you've

12:46

been looking at buying a more budget

12:48

friendly 385 nm resin printers, please

12:52

tell me why in the comments. But for

12:54

now, I'm going to come back to my

12:55

earlier analogy and just say, "Yeah, the

12:58

normal GK3 doesn't penetrate as deep,

13:01

but it works just fine." But if you do

13:04

decide to buy this one, I'd expect it's

13:06

because you want a GK3 thanks to the

13:08

easily changeable screen and the other

13:10

two models are just out of stock. And if

13:13

you do buy and this video has helped you

13:15

at least expect what you're getting for

13:17

your money, then I'd appreciate you

13:18

using my affiliate links in the

13:20

description before your purchase. That

13:22

nets me a commission at no cost to you

13:24

and is genuinely how I fully afford to

13:26

run this channel. You know, by eating

13:29

and staying alive. But above all else, I

13:32

want to say thanks for watching. A like,

13:33

a comment, or hitting subscribe goes a

13:35

long way. And you could also join our

13:37

members who are on screen now, who get

13:39

early access, Discord rolls, some

13:41

exclusive videos, mostly of me waffling.

13:43

But until next time, I could do

13:45

something heroic, but I've just put a

13:47

pizza in. Fauxhammer out.

13:54

[Music]

#Consumer Electronics

#Engineering & Technology