Click "...more" to see all Buying and review links for this video.

All links in our video description are affiliate links. Clicking these and making any purchase will earn us a commission at no cost to you

Buy your printers here (Alphabetical Order)

Anycubic Photon D2 - https://geni.us/PhotonUltra

Amazon - https://geni.us/AnycubicPhotonD2

Anycubic Photon Mono 2 - Anycubic - https://geni.us/PhotonMono2

Amazon - https://geni.us/AnycubicPhotonMono2

Anycubic Photon Mono X 6k S - https://geni.us/MonoX6Ks

Amazon - https://geni.us/AnycubicMonoX6kS

Anycubic Photon Mono M5 - https://geni.us/PhotonM5

Amazon - https://geni.us/AnycubicPhotonMonoM5

Anycubic Photon Mono M5s - https://geni.us/PhotonM5s

Amazon - https://geni.us/AnycubicPhotonMonoM5s

Elegoo Mars 3 Pro -https://shareasale.com/r.cfm?b=2183270&u=3060349&m=104244&urllink=&afftrack=

Amazon - https://amzn.to/3M3Mw45

Elegoo Mars 4 - https://shareasale.com/r.cfm?b=2351049&u=3060349&m=104244&urllink=&afftrack=

Amazon - https://amzn.to/48WLaC0

Show More Show Less View Video Transcript

0:00

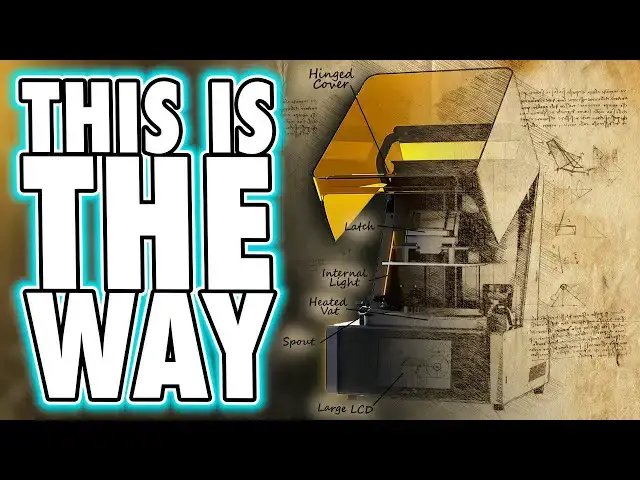

I've spent the last year looking at all

0:01

of the top resin printers on the market

0:03

there are some good ones and

0:04

unfortunately some bad ones but right

0:07

now at the start of the new year I want

0:08

to look to the future I really want to

0:10

just go on a journey of imagination we

0:13

have all these great printers but what

0:14

will the future bring what should the

0:16

future bring and I'd love to hear your

0:18

thoughts too what do you want am I right

0:20

am I wrong please drop your thoughts

0:22

down in the comments section as I plan

0:23

to use them in future videos at the very

0:26

least I hope this will serve as a wakeup

0:28

call for the brands out there making

0:30

these printers it should also make it

0:32

easy for someone new to have a point of

0:34

reference a list of boxes they should

0:36

tick if they want to create the world's

0:38

next leading consumer resin printer so

0:41

let's get on with making things easy for

0:43

the printer brands by telling them what

0:45

we want hi I'm Ross and this is f Hammer

0:51

videos so for the format of this video I

0:53

want to go through all the different

0:54

features and functions of a printer and

0:56

talk about who's given us the best as a

0:58

springboard for what we want going going

1:00

forward and I was going to end with the

1:02

style of the printer once going through

1:03

all of the different features we'd

1:05

finish on the housing to put this all in

1:07

but in reflection if I'm watching this

1:09

I'd kind of want to be able to picture

1:11

it in my mind up front so when choosing

1:13

the style of the best 3D printer out

1:15

there I'd like to take some massive

1:17

design cues from the hay Gear's

1:19

ultracraft reflex I mean this is an easy

1:22

pick surely the machine is gorgeous but

1:26

beyond that there are a ton of

1:27

functional elements in its form factor

1:29

too I mean I don't know anybody who

1:32

likes lift off Lids except maybe the few

1:34

people who use their printers in a print

1:35

farm and never have the lids on anyway

1:38

because they just keep the whole place

1:39

at room temperature there have been a

1:42

few other printers with liftup lids but

1:44

the two which come to mind most recently

1:46

are the Frozen Mega 8ks and the Nova 3D

1:49

whale 3 whilst the Frozen model has a

1:51

nice strong hinge mechanism that keeps

1:53

the lid in place as you lift it or lower

1:55

it both printers suffer from the rais

1:58

lid protruding out the back meaning

1:59

meaning you need your printer a good

2:01

distance away from the

2:02

wall the gk2 has a lift up lid but the

2:05

hinges are a bit weak and the rear

2:07

chassis curves a good 2/3 around the

2:09

sides as it covers around the build area

2:12

the reflexes lid is both angled and

2:15

hinged in such a way that it clears

2:17

plenty of space for accessing the

2:18

printer's internals whilst only taking

2:21

up additional height in your workspace

2:23

rather than empty depth too but yeah in

2:26

taking up height they would lose a lot

2:28

of customers in those forementioned

2:30

print Farms who just don't have that

2:32

height spare so however it's done design

2:35

the lid mechanism in such a way that

2:37

with only a few screws or such you could

2:39

swap this mechanism over to a lid which

2:42

can be removed entirely by just pulling

2:44

it towards you and away from the machine

2:46

but it's not just the functional feature

2:48

of that design either the visual style

2:50

of the machine and the materials all

2:52

feel robust and solid even the colorway

2:55

makes this come across as a more

2:56

professional tool than the Cheapo

2:58

plasticky of more affordable models like

3:01

most elegu and any cubic machines I do

3:04

wish however the lid was more

3:05

translucent because it's hard to see

3:07

inside this one and I also wish it was a

3:09

brighter orange what it matches my

3:12

branding of course I want a metallic

3:13

gray and orange printer when we look

3:16

inside the machine the next thing I want

3:17

to talk about is the build plate when it

3:19

comes to this component adherence is key

3:22

and I suspect many people would want me

3:23

to say they should come with a magnetic

3:25

build plate now I do see the benefit in

3:28

this where at the manufact ERS who

3:30

installed them in such a way that would

3:32

ensure that they won't come un stock but

3:35

I see so many issues with people self

3:37

installing third party ones that they

3:40

make me nervous to the point that I'm

3:42

not going to try them but as I said I do

3:45

see the benefit that you can easily pop

3:47

these off and the flex will allow you to

3:49

break models base layers away much

3:51

easier now personally I don't care if

3:53

this build surface is textured or even

3:55

laser etch like the satin printers or

3:58

smooth like on the gk2 once you've got

4:00

your base layers dialed in properly you

4:02

should have no adherence issues during

4:04

print and no over adherence after a

4:06

print though got to consider everyone

4:09

and if a bill play isn't smooth you'll

4:11

end up with some texture and that could

4:12

put off some buyers who do resin print

4:15

direct from the plate rather than

4:16

support models so I guess yeah if done

4:19

right I would like to see removable

4:21

flexible surfaces properly integrated

4:23

into printers perhaps in a variety of

4:25

styles and textures like on fdm printers

4:28

it could be cool if they add this I just

4:31

hope it includes some kind of Notch for

4:33

easy one-handed alignment the other

4:35

thing I want to talk about here is the

4:36

shape of the build plate because so far

4:39

only uniformation made a build plate

4:41

that combats this and that's a build

4:42

plate that keeps the top out of the vat

4:45

and yeah the gk2 plate may look heavy

4:47

and clunky but it's actually quite light

4:49

because well it's plastic but I'm sick

4:51

of having to wait every time a print is

4:53

complete for the resin to run off the

4:55

plate or to need to scrape it off myself

4:57

before I can move the plate to my

4:58

workbench for cleaning so if we aren't

5:01

getting removable flexible print

5:03

surfaces let's at least keep the top of

5:05

the bill plate out of the resin please

5:07

now when it comes to the connection to

5:08

the Zed arm well it's easy this one

5:11

enough with the bolts people and if

5:12

you're going to do bolts then do the

5:14

asymmetrical Leever style used on the

5:16

Nova 3D whale SE or the elu Jupiter SE

5:19

because they are much easier to loosen

5:21

and tighten but ideally a nice latch as

5:24

seen on the gk2 or the ultracraft reflex

5:27

would be ideal because that's really

5:28

simple to put the bill plate in and

5:30

pulled the latch down to lock it in

5:32

place one-handed because your other hand

5:34

is probably holding models or a tool or

5:36

is just covered in resin for the Zed

5:38

rail I'd say we'd like two rails but I

5:41

think that's obvious no matter how big

5:42

or small the print bed is stability

5:44

across the width of the arm is key and

5:47

when it comes to the screw for the

5:48

mechanism the ball screws are much

5:50

smoother than lead screws so yeah I'd

5:53

really like to see more of those

5:54

imprinters going forward especially if

5:56

you want to be classed as a quality one

5:58

as for the rotation of of this screw

6:00

well manufacturers I think should be

6:02

aware that we really need a motor

6:03

capable of a 20 Micron increment of the

6:06

plate lift height we already have

6:08

screens with sub20 Micron pixels let's

6:11

make sure we can match that in the Zed

6:13

height too or at the very least hey

6:15

Brands why don't you start publishing

6:17

the minimum step distance with your

6:19

printers if it's six microns cool but

6:21

just tell us clearly at least then we

6:24

can reduce the layer height to 18

6:25

microns instead of rounding up to 20 and

6:28

having the printer compensate for us

6:29

every few layers please just allow us to

6:32

be accurate and when it comes to speed

6:35

well the minimum movement speed I've

6:37

Ever Needed on PFA film is 60 mm a

6:41

minute or also known as 1 mm a second so

6:44

it needs to be able to go at least this

6:46

slow if it goes too fast it won't work

6:48

with some of the higher quality resins

6:50

and by quality I mean print quality and

6:53

for those out there who want fast

6:54

printers well the brands are now

6:56

competing with the likes of the Frozen

6:58

Mega 8ks which is a apparently capable

7:00

of 1200 mm a minute or 20 mm a second

7:04

and yeah that's far beyond what the

7:05

materials and pull forces are capable of

7:08

but since it's been done let's just call

7:10

this The Benchmark set and let the

7:12

materials catch up next on to the vat

7:16

and the first bit is simple make it

7:17

metal so you don't look cheap but if you

7:19

are going to make it plastic at least

7:21

make it translucent so that the few

7:23

times when we're using translucent resin

7:25

we might be able to see the layers

7:26

before they start to rise out of the vat

7:28

that would be handy

7:29

and you should also all everyone should

7:33

put a protruding Sprout on one corner

7:35

not just a different shaped corner but

7:37

an actual spout that sticks out of the

7:39

vat again like on the ultracraft reflex

7:43

so at least then when you're pouring

7:44

resin out of it it doesn't run down and

7:47

under the vat and risk going onto the Fe

7:49

or just drip everywhere and the other

7:51

thing this must have is an integrated

7:53

heater within the vat itself this has

7:55

been done on the Apex maker X1 it's the

7:58

most efficient way to heat resin and it

7:59

should be adopted by every brand and be

8:02

in every printer perhaps I don't know

8:04

give us the option to get a vat without

8:06

it to save costs but there should

8:08

definitely be an option for a heat on

8:10

every single printer made going forwards

8:13

and I know people talk about chamber

8:14

heaters but they warm the resin in the

8:16

vat last after heating the air in the

8:19

chamber and the already cured model

8:21

they're certainly useful as an addition

8:23

to a vat heater or a heater below the

8:25

resin chamber but alone they're not the

8:28

best approach

8:29

as for a release film well this might

8:31

not surprise anyone PFA all the way for

8:34

quality but ACF needs to be available as

8:37

an option for those happy to sacrifice a

8:39

bit of quality for an improved print

8:41

speed and finally when attaching the vat

8:44

to the printer no more bolts please once

8:46

again I'll sight The ultracraft Reflex

8:48

here give us some nice latches or like

8:50

the gk2 have a way to lock it in place

8:53

and whilst you're at it put some

8:55

comfortable handles on the vat itself

8:56

too please and finally something that

8:58

I'm just just making up out of nowhere

9:00

I'd really like someone to come up with

9:02

a better way of attaching the release

9:04

film to the vat itself because the

9:06

current process just it takes forever to

9:08

swap the film on any printer that's our

9:11

main technical Parts covered I want to

9:13

quickly talk about an important function

9:15

leveling first off instead of spending

9:17

the whole video imagining what we want

9:19

let's talk about what we don't want and

9:21

what we don't want is the stupid elu

9:23

ball mount on any printer and to the

9:25

seven of you who have never had problems

9:27

with yours feel free to to voice your

9:29

opinion in the comments below I know you

9:31

will and I like when you do it because

9:33

your interactions increase the reach of

9:35

this video so thanks for your help while

9:37

you're having a go at me look I know I'm

9:39

having a crack But please understand

9:41

that I've seen more comments in

9:42

agreement with this than the few of you

9:44

who don't need to relevel every three or

9:46

four prints and the typical fourpoint

9:48

screw mechanism used on every other

9:50

printer out there is certainly the

9:52

better option when done right but

9:54

honestly neither of these are the best

9:56

and that's what this video is about

9:58

right the best of everything the best

10:00

mechanism I've seen so far for leveling

10:02

the plate is used on printers like the

10:04

Apex maker X1 Frozen's Mega 8K printers

10:07

and the gk2 just to name a few of them

10:10

these use a set of inner grub screws

10:12

that set the level of the bed To Each

10:13

corner and then four outer screws which

10:16

go in the opposite direction to lock

10:18

them in place it's easy to level these

10:20

when you understand it but because I'm

10:21

yet to see one like this unlevel itself

10:24

in my opinion they should be pre-leveled

10:26

from the factory anyway and whilst we're

10:28

on the inside of this imaginary printer

10:30

let's talk about some other things we

10:32

want to get inside there shall we one is

10:34

a carbon filter like what elu has been

10:37

giving us but a better one these

10:39

shouldn't be running for the whole print

10:40

because that just wears them out faster

10:42

but it's definitely better to have one

10:44

circulating the air inside the chamber

10:46

and therefore keeping it running through

10:48

the filter over and over rather than

10:50

what elgu's done with the Mars mate and

10:52

pump it all out into your room and it'd

10:55

be nice to see these with some kind of

10:56

air quality sensor inside the chamber

10:58

too so then at least you know when it's

11:00

safer to open the lid this is probably

11:02

super expensive but again guys we're

11:04

wishing for stuff here and despite this

11:06

being in there I'd still also like to

11:08

see an optional vent cover like we have

11:11

on pretty much any of elgu's large

11:12

printer lids and also on the mega 8 KS

11:15

from Frozen with this at least we'd have

11:17

the option to pump Vapors outside and

11:20

then there's the resin pump I've said

11:21

many times that well I'm personally not

11:23

a fan of these because they're just too

11:25

messy if you're going to do one do it

11:27

but it needs some way of being

11:29

compatible with all the bottle types or

11:31

give us some empty containers like any

11:33

cubic did with the wash and cure Max and

11:35

the flip your bottle upside down options

11:37

never seem to do so well the one on the

11:40

Nova 3D printers just worries me and the

11:42

one on the ultracraft reflex is well

11:45

it's over engineered and in both cases

11:47

when swapping the bottle out they drip

11:49

everywhere so if you are going to offer

11:52

this then I like Frozen's approach make

11:54

it an optional extra for those people

11:56

who don't mind paying more to have it

11:58

and keep the pr inter costs down a bit

12:00

and speaking of Frozen one thing they

12:02

added on the MTI 8K that completely

12:04

failed was the camera but this is not a

12:07

bad idea for a feature if you're going

12:09

to do this you should do this take a

12:12

leaf out of Bamboo's book and put a

12:14

couple of very good bright lights in

12:16

your chamber so we can actually see the

12:18

model printing when checking on it

12:19

overnight and not just a silhouette

12:21

because the only light in the room comes

12:23

from outside of the printer case and

12:25

since most cameras are widescreen it

12:27

would make sense to orient it sideways

12:29

however so we can see more height than

12:31

width in the image make sure it's a

12:34

decent 1080p camera but give us the

12:36

option to upgrade to 4K if you can and

12:39

make sure the printer automatically

12:40

creates time lapses by taking a photo

12:42

when the bed lifts for each layer you

12:45

might be thinking that's an arbitrary

12:46

feature but actually if you included

12:49

that function everyone online would

12:51

share videos of your printer on social

12:53

media saying look at this that I printed

12:55

on that yes it's an expensive component

12:57

guys but it's also free marketing

13:00

afterwards so moving out of the printer

13:02

and back to the externals I'd like to

13:03

talk about ports the power socket hole

13:06

needs to be on the back of the printer

13:07

along with any type of network interface

13:09

such as ether a or anything else special

13:11

that you want to put on there that's

13:13

used by just a handful of people USB

13:16

ports should be on the front if you're

13:18

going to add Wi-Fi and you should add

13:20

Wi-Fi because in this day and age even

13:22

some toasters kettles and microwaves

13:24

have Wi-Fi but if you're going to add

13:26

Wi-Fi then please make sure the aerial

13:28

for it is inside the chassis and not

13:30

sticking out the side somewhere and the

13:33

remaining key feature is well it's the

13:35

interface with the printer this needs to

13:38

be a capacitive touchcreen and my

13:39

favorite interfaces so far are between

13:42

the satin 3 Ultra and the Apex maker X1

13:45

the former has a lot of controls and

13:47

it's very intuitive everything is well

13:49

translated and all the options are in a

13:51

sensible place but the much larger

13:54

approach taken by Apex maker is really

13:56

impressive it's just a shame that it's

13:58

let down by a few unintuitive icons and

14:01

an incomplete translation as a note to

14:03

all printer makers this is one of the

14:05

most important features of your machine

14:07

it's how your user commands the printer

14:09

to do things make it sexy make it fast

14:12

and make all of the most common features

14:14

be on the front and most obvious screen

14:17

secondary functions on the next and any

14:19

anciliary function should be on a third

14:21

or even fourth level that's it also when

14:25

the printer's printing show us

14:26

meaningful info show us a Rend of what

14:29

the currently exposed layer looks like

14:31

show us some info about the temperature

14:33

and other settings that are happening

14:34

inside the machine at the time that are

14:37

important that you might want to know

14:39

when a print is printing but more than

14:41

anything please show us a clear progress

14:44

bar with a countdown timer telling us

14:46

how long in time until the print is done

14:49

and then external to this but also in

14:51

controls please stop it with all the

14:53

proprietary weird apps to connect to

14:55

Wi-Fi and all that lock too we all know

14:58

how smart phones work the UI designers

15:00

surely have one so make all of the setup

15:02

controls as simple as a phone app and if

15:05

you're going to make a phone app too so

15:06

we can I don't know remotely monitor the

15:08

prints or control it from our phones

15:11

please make sure it's nothing like

15:12

reality Cloud's fomo style Hard Sell of

15:15

absolute crap and its unintuitive

15:18

storefront be like anchormate be like

15:20

bamboo handy then build your storefront

15:23

from a solid and sensible Foundation

15:25

once everything else Works in a good way

15:28

I mean it doesn't sound like this is too

15:30

hard yet so many Brands get it very

15:32

wrong disappointed and it will be the

15:35

first thing that was reviewers slate

15:37

when lazy design makes it harder than it

15:39

needs to be to use a printer and finally

15:42

some functional features all printers

15:45

should come with a built-in series of

15:46

exposure tests built into the onboard

15:48

control system or UI and it should walk

15:51

you through things like leveling and

15:52

further testing on the UI it should have

15:55

you print a load of squares at different

15:57

base exposure times s in one print so

15:59

you can see which one's stuck and which

16:01

ones are too stuck from this you can

16:04

then determine what your best base

16:05

exposure time is and all printers should

16:08

do what any cubic offers and let you

16:10

print a resin exposure Rangefinder at

16:12

different exposure times on one plate

16:15

and then the UI should explain to you

16:17

how to determine which one the best is

16:20

and it should then let you walk through

16:21

a series of further test to determine

16:23

things like best lift speed again this

16:25

should all be on the UI and explain how

16:27

to work out what fails look like and

16:30

finally it should let you then use these

16:32

daring settings to test different

16:33

amounts of anti-aliasing to remove all

16:36

traces of voxal and layer lines with

16:38

minimal impact on detail would this take

16:41

some time for a person to do yes but to

16:43

dial in your printer perfectly anyway

16:45

you need to do this anyway and everyone

16:47

in the world needs to learn how to do it

16:49

with a myriad of different tests and

16:51

opinions out there hoping that they've

16:53

guessed and have the best results yet

16:56

they have no validation this is why the

16:58

printer should do this and that's how

17:01

bamboo won the fdm race by having things

17:04

like calibration already set for the

17:06

user or it walks them through it and

17:08

holds their hand from the slicer and I

17:11

also want to talk about a feature that

17:12

most of you have probably never heard of

17:15

these home printers need a way for

17:17

increasing the exposure time or ideally

17:19

intensity of just the supports layer

17:22

times are so fast now anyway that it's

17:24

the lift and retract speed slowing down

17:26

resin printing so we have plenty of time

17:29

to even double up our exposure times and

17:31

still get fast prints and since we don't

17:34

have Direct Control why can't a brand

17:36

already figure out some way of when the

17:38

bed lowers it cures the objects layer

17:41

and then without moving dynamically

17:43

increases the light intensity and cures

17:45

the supports separately before lifting

17:48

and why would you do this well this

17:50

would actually Harden the supports more

17:52

and make them more brittle which means

17:54

as you pull them away from the model the

17:56

supports themselves are the weaker part

17:58

of the object and are the more likely

18:00

failure point this is what industrial

18:02

printers do in order to make parts that

18:04

are needle thin break away from supports

18:06

without any damage and doing this would

18:08

be a complete resin game Cher and

18:11

another thing that should be baked into

18:13

slices is some kind of test similar to

18:15

the cones of calibration where different

18:17

amounts of material are supported by

18:19

different thicknesses of material by

18:21

printing something like this and telling

18:23

the slicer which ones failed it would go

18:25

a long way to informing the slicer which

18:27

supports or even just parts of the model

18:30

would fail before you even start a print

18:32

because it would have been able to

18:34

determine the maximum pull forces on

18:36

different diameters of material and how

18:38

much material each of them is expected

18:40

to hold once we had something like this

18:43

Auto supports would become an absolute

18:45

Breeze but that requires someone to

18:47

actually spend time in developing one of

18:49

these slices alongside the printer

18:51

hardware and thus far every brand has

18:54

relied on chitubox lchi or Tango and

18:57

done little more than Rebrand one of

18:59

those apps to their own right then as

19:01

always we leave the best to last the

19:04

screen and as I read through this and

19:06

realize how much of my scripts I've got

19:07

to go probably should have made this a

19:09

separate video so I'm going to try and

19:11

give you the cliff notes and then I'll

19:12

do that another time now the first thing

19:14

I want to say is considering the screen

19:16

is a replaceable part everybody should

19:19

do what uniformation has done and make

19:21

it so that it's easy to access that

19:23

component with pretty much every printer

19:26

ever it's half a tear down to get access

19:28

to the screen in order to replace it

19:30

with the gk2 you pop out four screws

19:33

flip up a latch for a ribbon cable and

19:35

put the new screen in now coming back to

19:38

Imagining the final parts of the printer

19:40

I honestly don't care what the screen

19:42

size is the screen size should cater for

19:45

the needs of the user and the size of

19:47

the screen and the cost of the printer

19:49

should increase or decrease accordingly

19:51

based on how big or how small it is and

19:54

as I talk about this I've got no idea

19:56

how these things are made I have no idea

19:57

how any of this is made nor do I even

19:59

care I'm just saying what we should have

20:01

much cleverer people than me need to

20:03

work out how to actually do it but

20:05

whatever the screen size is it's the

20:06

pixel size that matters and please stop

20:09

chasing 8K 12K 24K 62k whatever let's go

20:14

through some math and by that I mean

20:16

insane math that I got off the internet

20:18

and pulled a couple of bits chucked it

20:19

all into Excel got a result and it kind

20:22

of make sense as we've learned from

20:24

retina displays the human eye cannot see

20:26

a difference between pixels when there

20:28

are around 326 pixels per inch and

20:31

you're holding it about a foot away from

20:33

your face now this is where I once again

20:35

talk crazy math in a video but go with

20:37

me and tell me if my theory is wrong in

20:38

the comments so here we go first of all

20:41

yes we'd all love this screen to be DLP

20:44

but nobody's driving DLP technology

20:46

forward as much as LCD we are years away

20:48

from seeing these resolutions on DLP if

20:51

not decades or even never but with

20:53

Technologies like cob light sources for

20:55

even distribution of UV light across the

20:57

display and forel lenses LCD is actually

21:01

close to matching the sharpness of DLP

21:03

now anyway but for the math go with me

21:06

let's assume we have a pixel density of

21:08

326 PPI like on the retina display and

21:12

let's take the Saturn 3 as our subject

21:14

to use a pretty standard size of the

21:16

x-axis print volume which is

21:19

28.8 mm in inches this would be around

21:22

8.62 in multiplying the width in inches

21:25

by 326 pixels per inch to tells us that

21:28

this imaginary screen would have 2,810

21:32

pixels on the x-axis so if we divide the

21:36

2.88 mm of that access by the number of

21:39

pixels in it that tells us that we would

21:41

have a pixel width of 78 microns and

21:45

let's just assume that this display has

21:46

Square pixels just to avoid any

21:48

confusion and I didn't need the printer

21:50

in the math I could have worked this out

21:51

from the same just using 1 mm but then

21:54

I've have nothing to show on screen and

21:55

this is a printer's video so if the

21:57

logic of written and the displays is

21:58

correct and that the human eye can't

22:00

determine the difference between pixels

22:01

at 326 pixels per inch or on pixels that

22:04

are 78 microns in size when they're 12

22:06

in away from your eye how then are we

22:08

able to see voxal lines on prints with

22:11

screens where the pixels are as low as

22:13

50 microns well here's my theory with

22:16

Retina displays it's a flat 2D plane but

22:19

your eyes have a special power when

22:21

you're lucky enough to have two of them

22:23

you can also register depth an

22:25

additional Dimension that is not present

22:27

on 2D screens these three-dimensional

22:30

objects are also affected by light

22:32

bouncing off the edges differently which

22:34

accents the forms and due to the

22:36

Cinematic lighting I tend to use in my

22:37

videos I always light subjects from the

22:40

side which makes things stand out more

22:42

light things from the front and those

22:44

voxal lines start to disappear and blur

22:46

so okay let's account for that special

22:49

depth Power by doubling the PPI to

22:52

652 and using the same math in Excel the

22:56

pixel size goes down to 39 microns and

22:58

this is where things start to become a

23:00

little less obvious this is the same in

23:03

Zed resolution too for those of you

23:04

still printing at 50 Micron layer

23:06

Heights also as an additional FYI most

23:09

of the industrial DLP printers used in

23:11

the production of things like Miniatures

23:13

operate at around 38 microns in pixel

23:16

size anyway and that's because the

23:18

industry manufacturers know that this is

23:20

as much as you probably need and when

23:23

you're around this size you just need to

23:25

add the smallest amount of anti-aliasing

23:27

and you don't need to push the

23:28

technology further to improve the detail

23:30

Beyond reasonable bluring the surface on

23:33

the edge of each layer projection will

23:35

soften all of that out without any

23:37

distinguishable loss of detail to the

23:39

overall

23:40

piece and I know there's a few of you

23:43

out there who are still thinking but

23:44

I've watched your videos F hammer and I

23:46

can still see voxal lines on your prints

23:48

with much smaller pixel sizes but again

23:51

let me stress the retina example on

23:53

phones is when the phone is 12 in from

23:55

your eyes that's a lot different to me

23:57

shooting images of it on my macro lens

23:59

and you watching it on your big screen

24:02

the model I always show of me wearing

24:03

power armor built with parts from atland

24:05

Forge is about as tall as my thumbnail

24:08

or 15 mm how many 15 mm can you fit in

24:12

the area of the screen that you're

24:14

looking at this model on and again

24:16

consider that the lighting also accents

24:18

all of the sharp edges and also when any

24:21

of us are out there shooting Miniatures

24:23

to share photos with our friends how big

24:25

are they on your screen compared to the

24:27

model itself if it's two times bigger

24:29

you'd need a printer with 19 Micron

24:31

pixels to hide those lines and we have

24:34

that in a way because these new 12K

24:36

screens have 19 Micron pixels on the

24:38

x-axis but as I look back at my Mars 4

24:41

reviews I can't see any box or lines

24:43

when I zoom in with its 18 Micron Square

24:47

pixels only the layer lines are visible

24:49

and they're 30 microns and if you wanted

24:52

four times magnification which isn't

24:54

realistic for Miniatures when you're

24:56

seeing them on a computer screen you'd

24:58

actually need 10 Micron pixels for them

25:00

to Disappear Completely so as I've said

25:03

now for over a year just enable

25:05

anti-aliasing and be happy with what

25:07

your printer does I think no matter what

25:09

printer screen size we go for yeah we

25:12

should aim for all printers to have sub

25:14

20 Micron pixels and we should print at

25:17

20 Micron layer Heights for the most

25:19

detailed prints which will allow for two

25:21

times magnification without these lines

25:23

being significantly visible but even

25:26

then you may as well enable antialiasing

25:28

to smooth everything out perfectly

25:29

anyway and to avoid any light cast

25:32

highlighting them but the thing I want

25:34

to see the most is Brands need to stop

25:36

chasing this resolution metric because

25:39

well I hope I've kind of theoretically

25:42

proven here it's

25:43

pointless and we're all sick of it and

25:46

besides no matter how good the screens

25:48

are getting most resins can't render

25:50

that level of detail anyway I hope my

25:52

insane math and specious logic Mak sense

25:55

and I hope you enjoyed coming on this

25:56

journey with me hope hopefully now we

25:58

will get some Brands listening and

25:59

heading towards this more than anything

26:02

I'd like to see all the companies

26:03

released finished printers you'll see on

26:05

my channel I haven't reviewed the Athena

26:07

yet and that's because they aren't

26:09

releasing it until it's done and for

26:11

that alone I have very high hopes for

26:13

that printer and also printer brands if

26:15

you're going to give us a USB drive and

26:17

expect that to be a key part of the

26:18

machine please give us a decent quality

26:21

one or just don't bother I want to say

26:23

thanks for watching and thanks to our

26:25

members who help us make these videos

26:27

please consider join in to get some

26:28

benefits there is a link below this

26:30

video unless you're on iPhone the link

26:32

is in the description please don't

26:33

forget to like hit subscribe the

26:35

notification Bell but especially leave a

26:37

comment what do you think what do you

26:39

want in a future printer until next time

26:42

life finds a way faux hammer

26:46

[Music]

26:56

out